Page 92 - The Toyota Way Fieldbook

P. 92

Chapter 4. Create Initial Process Stability 69

30 Feet

Headlight Headlight Headlight Headlight Accessory

Seatbelt

Style D Style C Style B Style A Packs

Vehicle

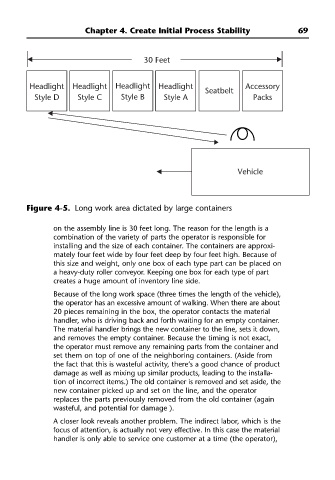

Figure 4-5. Long work area dictated by large containers

on the assembly line is 30 feet long. The reason for the length is a

combination of the variety of parts the operator is responsible for

installing and the size of each container. The containers are approxi-

mately four feet wide by four feet deep by four feet high. Because of

this size and weight, only one box of each type part can be placed on

a heavy-duty roller conveyor. Keeping one box for each type of part

creates a huge amount of inventory line side.

Because of the long work space (three times the length of the vehicle),

the operator has an excessive amount of walking. When there are about

20 pieces remaining in the box, the operator contacts the material

handler, who is driving back and forth waiting for an empty container.

The material handler brings the new container to the line, sets it down,

and removes the empty container. Because the timing is not exact,

the operator must remove any remaining parts from the container and

set them on top of one of the neighboring containers. (Aside from

the fact that this is wasteful activity, there’s a good chance of product

damage as well as mixing up similar products, leading to the installa-

tion of incorrect items.) The old container is removed and set aside, the

new container picked up and set on the line, and the operator

replaces the parts previously removed from the old container (again

wasteful, and potential for damage ).

A closer look reveals another problem. The indirect labor, which is the

focus of attention, is actually not very effective. In this case the material

handler is only able to service one customer at a time (the operator),