Page 96 - The Toyota Way Fieldbook

P. 96

Chapter 4. Create Initial Process Stability 73

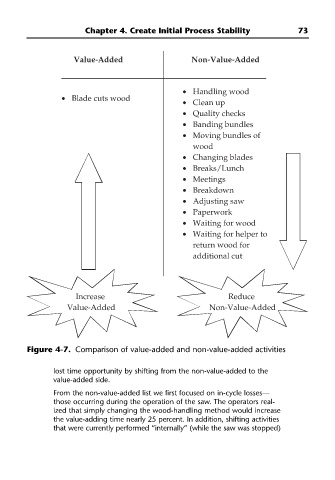

Value-Added Non-Value-Added

• Handling wood

• Blade cuts wood

• Clean up

• Quality checks

• Banding bundles

• Moving bundles of

wood

• Changing blades

• Breaks/Lunch

• Meetings

• Breakdown

• Adjusting saw

• Paperwork

• Waiting for wood

• Waiting for helper to

return wood for

additional cut

Increase Reduce

Value-Added Non-Value-Added

Figure 4-7. Comparison of value-added and non-value-added activities

lost time opportunity by shifting from the non-value-added to the

value-added side.

From the non-value-added list we first focused on in-cycle losses—

those occurring during the operation of the saw. The operators real-

ized that simply changing the wood-handling method would increase

the value-adding time nearly 25 percent. In addition, shifting activities

that were currently performed “internally” (while the saw was stopped)