Page 145 - The Tribology Handbook

P. 145

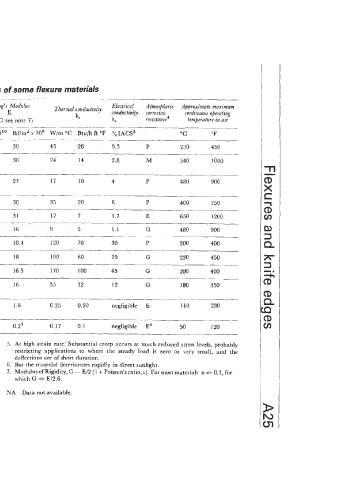

Table 25.2 Relevant properties of some flexure materials

Faiigue strength' T-Qu~~s .Maddicr Atmospheric Approximate maximum

E

Material ff (For G see note 7) k, k, resistance4 temperature in air

-

N/m2 x lo7 Ibf/in2 X lo3 N/mZ ~10'~ Ibf/in2 x IO6 W/m "C Btu/h ft "F %IACS3

N/mZ x IO7 Ibf/in2 x IO' ____ -- -_ --__ __ "C "F

_-

Spring steels o'6-1*oc 80-210 120-300 40-70 60-100 21 30 45 26 9.5 P 230 450

0.3-0.9Mn - _. _.___ - -

Carbon chromium stainless 150 200 60 85 21 30 24 14 2.8 M 540 1000

steel (BS 420 S45)

___l_l--___-- -

High strength alloy steels : 210 300 66 96 19 27 17 10 4 P 480 900

nickel maraging steel

DTD 5192 (NCMV) 210 300 80 115 21 30 35 20 6 P 400 750

Inconel X 165 240 65 95 21 31 12 7 I .7 E 650 1200

High strength titanium alloy 95 140 65 95 11 16 9 5 1.1 G 480 900 -

R High strength aluminium alloy 50 - 73 15 - 7.2 10.4 ! 20 70 30 P 200 400

22

tn

h) Beryllium copper 90 I35 38 55 12.5 18 100 60 25 G 230 450

Low beryllium copper 65 95 24 35 11.5 16.5 170 100 45 G 200 400

-

Phosphor bronze 60 90 20 29 11 16 55 32 12 G 180 350

(8% Sn; hard)

Glass fibre reinforced nylon 20 30 NA NA 1.2 1.8 0.35 0.20 negligible E 1 IO 230

(40% G.F.)

Polypropylene 3.7 5.45 NA NA 0.14 0.25 0.17 0.1 negligible E6 50 120

Notes: 1, Very dependent on heat treatment and degree of working. Figures given are typical of 5. At high strain rate. Substantial creep occurs at much reduced stress levels, probably

fully heat treated and processed strip material of about 0.1 in thickness at room restricting applications to where the steady load is zero or very small, and the

temperature. Thinner strip and wire products can have higher yield strengths. deflections are of short duration.

2. Fatigue strengths are typical for reversed bending of smooth finished specimens sub- 6. But the material deteriorates rapidly in direct sunlight.

jected to lo7 cycles. Fatigue strengths are reduced by poor surface finish and corrosion, 7. Modulus of Rigidity, G = E/2 (1 +Poisson's ratio, v). For most materials u 0.3, for

and may continue to fall with increased cycles above IO7. which G E/2.6.

3. Percentage of the conductivity of annealed high-purity copper at 20°C.

4. Order ofresistanceon following scale: P-poor, M-moderate, G-good, E-excellen:. NA Data not available.

Note, however, that protection from corrosion can often be given to materials which

are poor in this respect by grease or surface treatments.