Page 149 - The Tribology Handbook

P. 149

Electromagnetic bearings A26

AXIAL BEARING CONFIGURATION

A flat, solid ferromagnetic disc, secured to the shaft is used as the collar for the axial thrust bearing. Solid disc

electromagnets are situated either side of the collar and operate in a similar manner to those in a radial bearing but in one

dimension only.

POSITION TRANSDUCERS

Two dimensions are controlled at each radial bearing location and one dimension is controlled at the axial bearing. One

transducer could be used for each dimension if it were totally linear and free from drift due to ageing or temperature effects.

Two transducers per dimension are, however, used in practice because they require only that a balance or difference be

maintained, tlhus cancelling unwanted &sets. A passive bridge system such as this greatly increases accuracy and reliability

without undue increase in cost or complication.

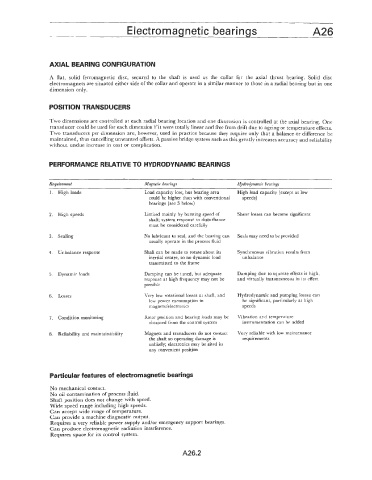

PERFORMANCE RELATIVE TO HYDRODYNAMIC BEARINGS

Requirement Magnetic bearings Hydrodynamic bearings

.,

1. Hkh loads Load capacity low, but bearing area High load capacity (except at low

could be higher than with c&ventional speeds)

bearings (see 3 below)

2. High speedis Limited mainly by bursting speed of Shear losses can become significant

shaft; system response to disturbance

must be considered carefully

3. Sealing No lubricant to seal, and the bearing can Seals may need to be provided

usually operate in the process fluid

4. Unbalance response Shaft can be made to rotate about its Synchronous vibration results from

inertial centre, so no dynamic load unbalance

transmitted to the frame

5. Dynamic loads Damping can be tuned, but adequate Damping due to squeeze effects is high,

response at high frequency may not be and virtually instantaneous in its effect

possible

6. Losses Very low rotational losses at shaft, and Hydrodynamic and pumping losses can

low power consumption in be significant, particularly at high

magnetdelectronics speeds

7. Condition monitoring Rotor position and bearing loads may be Vibration and temperature

obtained from the control system instrumentation can be added

8. Reliability and maintainability Magnets and transducers do not contact Very reliable with low maintenance

the shaft so operating damage is requirements

unlikely; electronics may be sited in

any convenient position

Particular features of electromagnetic bearings

No mechanical contact.

No oil contamination of process fluid.

Shaft position does not change with speed.

Wide speed range including high speeds.

Can accept wide range of temperature.

Can provide a machine diagnostic output.

Requires a very reliable power supply andlor emergency support bearings.

Can produce electromagnetic radiation interference.

Requires space for its control system.

A26.2