Page 155 - The Tribology Handbook

P. 155

Belt drives B1

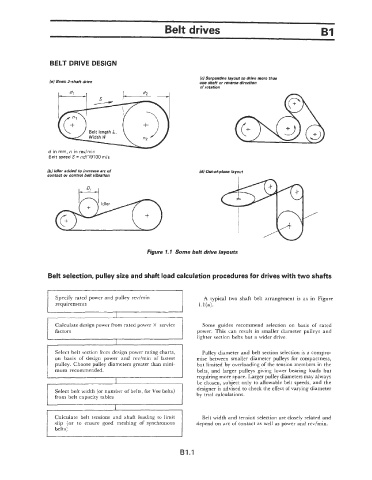

BELT DRIVE DESIGN

(c) Serpentine layout to drive more than

4al Basic &shaft drive one shaft or reverse direction

of rotation

d in rnm, n in rw/min

Belt speed S = r;rd/19100 mls

(b) Idler added to increase arc of (d/ Out-of-plane layout

contact or contro,t belt vibration

Figure 1.1 Some belt drive layouts

Belt selection, pulley size and shaft load calculation procedures for drives with two shafts

Specify rated power and pulley rev/min A typical two shaft belt arrangement is as in Figure

requirements 1.1 (a).

1

Calculate design power from rated power X service Some guides recommend selection on basis of rated

j factors power. This can result in smaller diameter pulleys and

r lighter section belts but a wider drive.

Select belt section from design power rating charts, Pulley diameter and belt section selection is a compro-

on basis of design power and rev/min of fastest mise between smaller diameter pulleys for compactness,

pulley. Choose pulley diameters greater than mini- but limited by overloading of the tension members in the

mum recommended. belts, and larger pulleys giving lower bearing ioads but

L tables ,I

requiring more space. Larger pulley diameters may always

be chosen, subject only to allowable belt speeds, and the

designer is advised to check the effect of varying diameter

Select belt width (or number of belts, for Vee belts)

by trial calculations.

capacity

belt

from

tensions and shaft loading to limit 1

[=elt Belt width and tension selection are closely related and

slip (or to ensure good meshing of synchronous depend on arc of contact as well as power and rev/min.

belts)

61.1