Page 262 - The Tribology Handbook

P. 262

Sealing against dirt and dust B20

Table 20.3 Sealing of reciprocating parts

~~

Method Description Comments

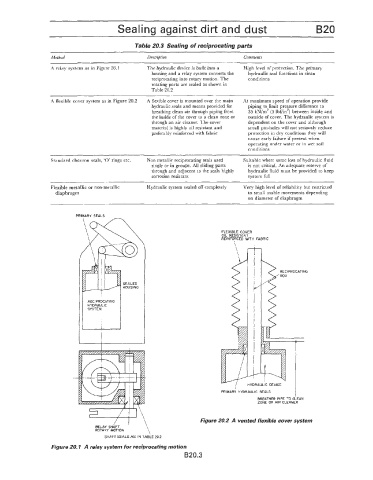

A relay system as in Figure 20.1 The hydraulic device is built into a High level of protection. The primary

housing and a relay system converts the hydraulic seal functions in clean

reciprocating into rotary motion. The conditions

rotating parts are sealed as shown in

Table 20.2

A flexible covcr system as in Figure 20.2 A flexible cover is mounted over the main At maximum speed of operation provide

hydraulic seals and means provided for piping to limit pressure difference to

breathing clean air through piping from 35 kN/m2 (5 Ibf/in2) between inside and

the inside of the cover to a clean zone or outside of cover. The hydraulic system is

through an air cleaner. The cover dependent on the cover and although

material is highly oil resistant and small pin-holes will not seriously reduce

preferably reinforced with fabric protection in dry conditions they will

cause early failure if present when

operating under water or in wet soil

conditions

~~~ ~~~

Standard chevron seals, '0' ring.s etc. Non metallic reciprocating seals used Suitable where some loss of hydraulic fluid

singly or in groups. All sliding parts is not critical. An adequate reserve of

through and adjacent to the seals highly hydraulic fluid must be provided to keep

corrosion resistant system full

Flexible metallic or non-metallic Hydraulic system sealed off completely Very high level of reliability but restricted

diaphragm to small usable movements depending

on diameter of diaphragm

FLEXIBLE COVER

OIL RESISTANT

REINFORCED WITH FABRIC

RECIPROCATING

SEALED

HOUSING

1 SYSTEM 1

RECIPROCATING

HYDRAULIC

PRIMARY HYDRAULIC SEALS

BREATHER PIPE TO CLEAN

Y\ ZONE OR AIR CLEANER

RELAY SHAFT Figure 20.2 A vented flexible cover system

ROTARY MOTtOlU

SHAFT SEALS AS IN TABLE 20.2

Figure 20. I A relay system for reciprocating motion

B20.3