Page 265 - The Tribology Handbook

P. 265

B21 Oil flinger rings and drain grooves

= 1.2

Figure 27.4 Throwers for mediumlhigh speeds

(TOP)

OIL DRAIN IBOTTOklI

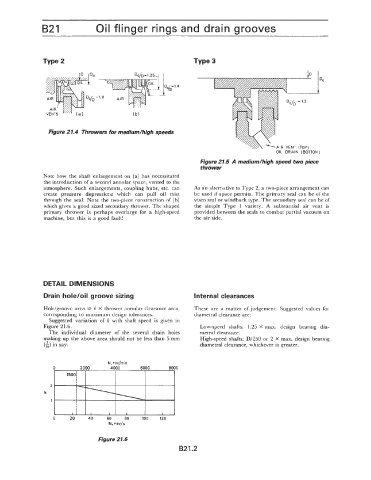

Figure 21.5 A medium/high speed two piece

thrower

Note how the shaft enlargement on (a) has necessitated

the introduction of a second annular space, vented to the

atmosphere. Such enlargements, coupling hubs, etc. can As an alternative to Type 2, a two-piece arrangement can

create pressure depressions which can pull oil mist be used if space permits. The primary seal can be of the

through the seal. Note the two-piece construction of (b) visco seal or windback type. The secondary seal can be of

which gives a good sized secondary thrower. The shaped the simple Type 1 variety. A substantial air vent is

primary thrower is perhaps overlarge for a high-speed provided between the seals to combat partial vacuum on

machine, but this is a good fault! the air side.

DETAIL DIMENSIONS

Drain hole/oil groove sizing Internal clearances

Hole/groove area 2 k X thrower annular clearance area, These are a matter of judgement. Suggested values for

corresponding to maximum design tolerances. diametral clearance are:

Suggested variation of k with shaft speed is given in

Figure 2 l .6. Low-speed shafts: 1.25 X max. design bearing dia-

The individual diameter of the several drain holes metra1 clearance.

making up the above area should not be less than 5 mm High-speed shafts: D/250 or 2 X max. design bearing

in say. diametral clearance, whichever is greater.

N, rev/min

0 2000 4000 6000 8000

2

k

1

0 20 40 60 80 100 120

N, rev15

Figure 21.6

B21.2