Page 269 - The Tribology Handbook

P. 269

B22 Labyrinths, brush seals and throttling bushes

BRUSH SEALS

Brush seals are an alternative for labyrinths in gas turbine

engine applications, reducing leakage by a factor up to five

or tenfold, although relatively expensive. The brush seal

comprises a bundle of metal filaments welded at the base.

The filaments are angled circumferentially at about 45

degrees, filament length is chosen to give an interference of

0.1-0.2 mm with the sealing counterface. Filaments are

typically about 0.7 mm diameter and manufactured from

such materials as high temperature alloys of nickel or

cobalt. Suitable counterface materials include hardfacings

of chromium carbide, tungsten carbide or alumina

rnrn

0.7 rnrn

Figure 22.5 Brush seal with typical dimensions

BLADE SPACING, in

LABYRINTHS

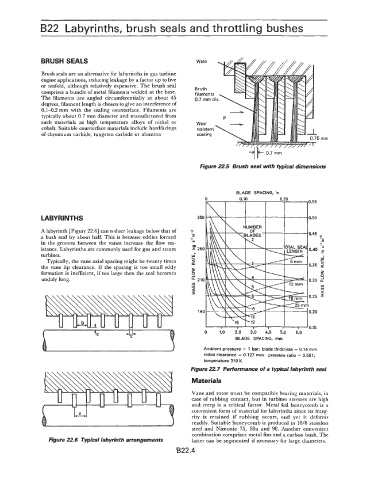

A labyrinth [Figure 22.61 can reduce leakage below that of

a bush seal by about half. This is because eddies formed

in the grooves between the vanes increase the flow res-

istance. Labyrinths are commonly used for gas and steam

turbines.

Typically, the vane axial spacing might be twenty times

the vane lip clearance. If the spacing is too small eddy

formation is inefficient, if too large then the seal becomes

unduly long.

0 1.0 2.0 3.0 4.0 5.0 6.0

BLADE SPACING, mm

Ambient pressure = 1 bar; blade thickness = 0.14 mm

radial clearance = 0.127 rnrn pressure ratio = 0.551;

temperature 310 K

Figure 22.7 Performance of a typical rabyrinth seal

Materials

Vane and rotor must be compatible bearing materials, in

case of rubbing contact, but in turbines stresses are high

and creep is a critical factor. Metal foil honeycomb is a

convenient form of material for labyrinths since its integ-

rity is retained if rubbing occurs, and yet it deforms

readily. Suitable honeycomb is produced in 18/8 stainless

steel and Nimonic 75, 80a and 90. Another convenient

combination comprises metal fins and a carbon bush. The

Figure 22.6 Typical labyrinth arrangements latter can be segmented if necessary for large diameters.

B22.4