Page 273 - The Tribology Handbook

P. 273

B23 Lip seals

Operating conditions

Up to 35 mm (liin) dia. Approx. 8000 rev/min

75 mm (3 in) dia. Approx. 4000 rev/min

Over 75 mm (3 in) dia. Approx. 15 m/s (50 ft/s) peripheral speed

Max. speed

Up to 75 mm (3 in) dia. Approx. 0.6 bar (10 p.s.i.)

Over 75 mm (3 in) dia. Approx. 0.3 bar (5 psi.)

By using a profiled backing washer to support the lip, pressures up to

Max. fluid pressure 6 bar (100 psi) can be accommodated

See table of rubber Permissible oil temperatures are set by the sealing lip material.

materials Do not ignore low-temperature conditions

Temperature

range

Housing Better than 0.25 mm (0.010 in) total indicator reading when clocked

from shaft

Shaft Depends on speed. Aim for better than 0.025 mm (0.001 in) total

indicator reading when rotated in its own bearings

Eccentricity

~

Housing Fine turned. Provide lead-in chamber

Shaft Grind and polish to better than 0.5 pm R,. Surface must be free from

all defects greater than 0.0025 mm (0.0001 in) deep. Use cardboard

protection sleeve during manufacture

Surface finish

Housing Up to 100 mm (4 in) 20.025 mm (0,001 in)

100-175 mm (4-7 in) 20.037 mm (0.0015 in)

Over 175 mm (7 in) k0.05 mm (0.002 in)

Shaft Up to 50 mm (2 in) f0.025 mm (0.001 in)

50-100 mm (2-4 in) 20.037 mm (0.0015 in)

100-200 mm' (4-8 in) k0.05 mm (0.002 in)

Machining tolerances Over 200 mm (8 in) k0.125 mm (0.005 in)

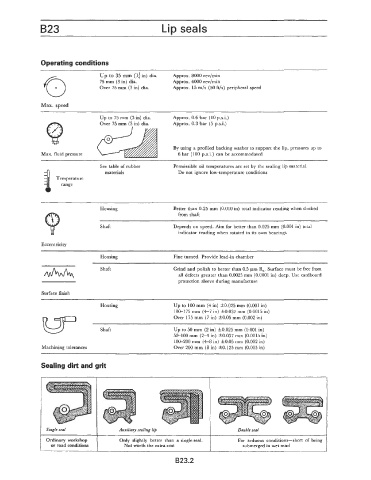

Sealing dirt and grit

1 single seal Auxiliary sealing lip I Double seal

I Ordinary workshop Only slightly better than a single seal. I For arduous conditions-short of being

~

or road conditions

submerged in wet mud

Not worth the extra cost

B23.2