Page 275 - The Tribology Handbook

P. 275

B23 Lip seals

SEALS FOR RECIPROCATING SHAFTS

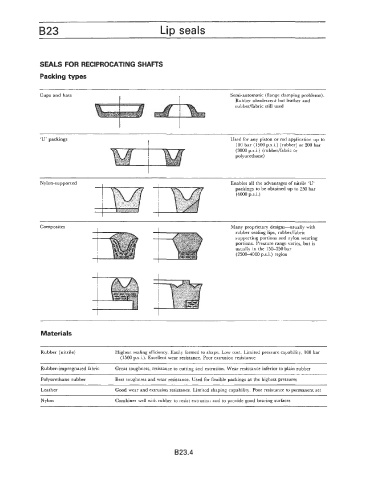

Packing types

Cups and hats Semi-automatic (flange clamping problems).

Rubber obsolescent but leather and

rubber/fabric still used

‘U’ packings Used for any piston or rod application up to

100 bar (1500 psi) (rubber) or 200 bar

(3000 psi) (rubber/fabric or

polyurethane)

N ylon-supported Enables all the advantages of nitrile ‘U’

packings to be obtained up to 250 bar

(4000 p.s.1.)

Composites I I Many proprietary designs-usually with

rubber sealing lips, rubber/fabric

supporting portions and nylon wearing

portions. Pressure range varies, but is

usually in the 150-250 bar

(250C-4000 psi) region

Materials

Rubber (nitrile) Highest sealing efliciency. Easily formed to shape. Low cost. Limited pressure capability, 100 bar

(1 500 p.s.i.). Excellent wear resistance. Poor extrusion resistance

Rubber-impregnated fabric Great toughness, resistance to cutting and extrusion. Wear resistance inferior to plain rubber

Polyurethane rubber Best toughness and wear resistance. Used for flexible packings at the highest pressures

~ ~~ ~ ~~~

Leather Good wear and extrusion resistance. Limited shaping capability Poor resistance to permanent set

Nylon Combines well with rubber to resist extrusion and to provide good bearing surfaces

823.4