Page 278 - The Tribology Handbook

P. 278

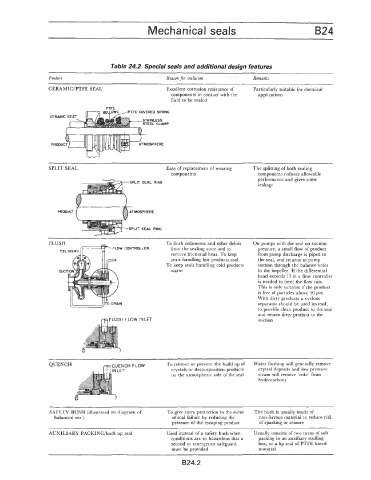

Mechanical seals B24

Table 24.2 Special seals and additional design features

Feature Reason for inclusion Remarks

CERBMIC/PTFE SEAL Excellent corrosion resistance of Particularly suitable for chemical

components in contact with the applica tiom

fluid to be sealed

PTFE

1- BELLOWS~,PTFE COVERED SPRING

PRODUCT 5G

SPLIT SEAL Ease of replacement of wearing The splitting of both sealing

components components reduces allowable

performance and gives some

leakage

PRODUCT

SPLIT SEAL RING

______

To flush sediments and other debris On pumps with the seal on suction

FLOW CONTROLLER from the sealing zone and to pressure, a small flow of product

remove frictional heat. To keep from pump discharge is piped to

seals handling hot products cool. the seal, and returns to pump

To keep seals handling cold products suction through the balance holes

warm in the impeller. If the differential

head exceeds 15 m a flow controller

is needed to limit the flow rate.

This is only suitable if the product

is free of particles above 50 pm.

With dirty products a cyclone

separator should be used instead,

to provide clean product to the seal

and return dirty product to the

~FLUS~Y FLOW INLET suction

QUENCH QUENCH FLOW To remove or prevent the build up of Water flushing will generally remove

crystals or decomposition products crystal deposits and low pressure

on the atmospheric side of the seal steam will remove ‘coke’ from

hydrocarbons

~~~

SAFETY BUSH (illustrated on diagram of To give extra protection in the event The bush is usually made of

balanced seal) of seal failure by reducing the non-ferrous material to reduce risk

pressure of the escaping product of sparking or seizure

AUXILIARY PACKING/back up seal Used instead of a safety bush when Usually consists of two turns of soft

conditions are so hazardous that a packing in an auxiliary stuffing

second or emergency safeguard box, or a lip seal of PTFE based

must be provided material

B24.2