Page 276 - The Tribology Handbook

P. 276

Lir> seals 923

Extrusion clearance-mmtin)

Up to 100 bar (1500 p.s.i.) 100-200 bar (150&3000 p.s.i.) Over 200 bar (3000 p.s.i.)

-

Normal Short lije Normal Short l$e Normal Short l$e

Rubber 0.25 (0.010) 0.5 (0.020) - - - -

~~ ~

Rubber/fabric leather 0.4 (0.015) 0.6 (0.025) 0.25 (0.010) 0.5 (0.020) 0.1 (0.005) 0.25 (0.010)

- -

Palyurethane 0.4 (0.015) 0.6 (0.025) 0.25 (0.010) 0.5 (0.020) 0.1 (0.005) 0.25 (0,010)

~ ~~

Nylon support - - 0.25 (0.010) 1.0 (0.040) 0.1 (0.005) 0.5 (0.020)

-

Diesign of metal parts

-

Cylinders Piston rods

-

Preferred materials Steel Steel

Cast iron

I

Heat treatment Not required Harden if possible

Plating

- Not required Chrome plate if possible

Surface finish Grind or hone Grind and polish

0.5 pm R, rnax. 0.5 prn Ra max.

-

Machining tolerances Fixed by extrusion clearance-see previous table

Friction

Friction varies considerably with working conditions but for preliminary design purposes it can be assumed that it will be

between 0.5% and 3% of the load which would be produced on a piston of the same diameter by the fluid pressure involved.

For more accurate values the seal manufacturer must be consulted.

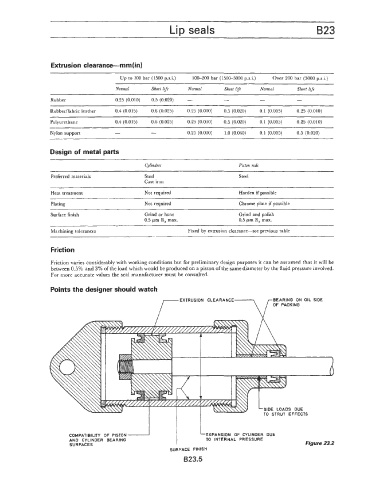

oints the designer should watch

EXTRUSION CLEARANCE BEARING ON OIL SIDE

OF PACKING

SIDE LOADS DUE

TO STRUT EFFECTS

!

COMPATIBILITY OF PISTON ‘-EXPANSION OF CYLINDER DUE

AND CYLINDER BEARING TO INTERNAL PRESSURE

SUR FACES Figure 23.2

SURFACE FINISH

B23.5