Page 277 - The Tribology Handbook

P. 277

B24 Mechanical seals

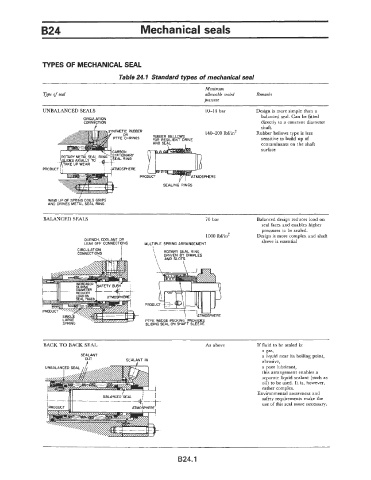

TYPES OF MECHANICAL SEAL

Table 24.1 Standard types of mechanical seal

Maximum

Type of seal allowable sealed Remarks

pressure

UNBALANCED SEALS 10-14 bar Design is more simple than a

balanced seal. Can be fitted

CIRCULATION

CONNECTION directly to a constant diameter

shaft.

lbf/in2 Rubber bellows type is less

sensitive to build up of

contaminants on the shaft

surface

PRODUC

WIND UP OF SPRI~G COILS GRIPS

AND DRIVES METAL SEAL RING

BALANCED SEALS 70 bar Balanced design reduces load on

seal faces and enables higher

pressures to be sealed.

1000 lbf/in2 Design is more complex and shaft

QUENCH, COOLANT OR

LEAK OFF CONNECTIONS MULTIPLE SPRING ARRANGEMENT sleeve is essential

CIRCULATION ! ROTARY SEAL RING

CONNECTIOYS DRIVEN BY DIMPLES

\ AND SLOT:

PRODUC

PTFE WEDGE PACKING PROVIDES

SLIDING SEAL ON SHAFT SLEEVE

BACK TO BACK SEAL As above If fluid to be sealed is:

a gas,

SEALANT a liquid near its boiling point,

OUT SEALANT IN

4 abrasive,

UNBALANCEOS a poor lubricant,

this arrangement enables a

separate liquid sealant (such as

oil) to be used. It is, however,

rather complex.

Environmental awareness and

safety requirements make the

use of this seal more necessary.

B24.1