Page 28 - The Tribology Handbook

P. 28

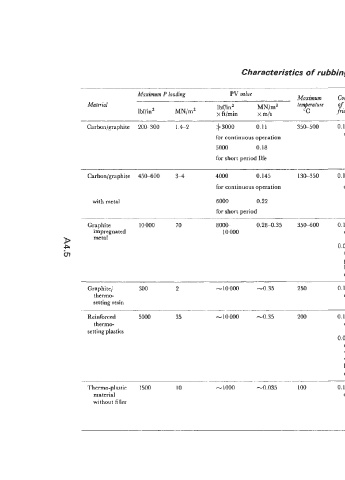

Characteristics of rubbing bearing materials

Maximum P loading PV value Cot$cient

Maximum Coejicient of

Msterinl ibfjin2 .niNim' tc%p&m $f expamion I?@&$

Ibf/in2 MN/mZ xft/min x rnis "C friction x 10-6/0c

Carbon/graphite 200-300 1.4-2 4 3000 0.11 350-500 O.lW.25 2.5-5.0 For continuous dry Food and textile machinery

dry operation where contamination by

for continuous operation

P$ 200 Ibf/in2 lubricant inadmissible; fur-

5000 0.18 ( 1.4 MN/m2), naces, conveyors, etc. where

"4 250 ft/min temperature too high for

for short period llfe

(1.25 m/s) conventional lubricants :

..

where bearings are immersed

Carbon/graphite 450-600 3-11 4000 0.145 130-350 0.1Ck0.35 4.2-5.0 Permissible peak load in liquids, e.g. water, acid or

and temperature alkaline solutions, solvents,

for continuous operation dry depend upon metal etc.

impregnant

with metal 6000 0.22

for short period Bearings working in dusty

atmospheres, e.g. coal-mining,

Graphite 10000 70 8000- 0.28-0.35 350600 0.10-0.15 12-13 with Operates satisfactorily foundry plant, steel plant,

impregnated 10 000 iron dry within stated etc.

D metal matrix limits; benefits

P 0.020- considerably ifsmall

cn 0.025 16-20 with quantity oflubricant

grease bronze present, i.e. higher

lubri- matrix PV values

cated

Graphite/ 300 2 -10000 -0.35 250 0.13-0.5 3.5-5.0 Particularly suitable for

thermo- dry operation in sea-water

setting resin or corrosive fluids

Reinforced 5000 35 -10000 -0.35 200 0.1-0.4 25-80 Values depend upon Water-lubricated roll-neck

thermo- dry depend- type ofreinforcement, bearings (esp. hot rolling

setting plastics ing on e.g. cloth, asbestos, mills), marine sterntube and

0.006 plane etc. rudder bearings ; bearings

claimed of rein- subject to atomic radiation

with force- Higher PVvalues when

water ment lubricated

lubri-

cation

Thermo-plastic 1500 10 - 1000 -0.035 100 0.1-0.45 -100 Higher PVvalues accept- Bushes and thrust washers in

material dry able if higher wear automotive, textile and food

without filler rates tolerated. With machinery--linkages where

initial lubrication only, lubrication difficult

PVvalues up to20000

can be imposed