Page 33 - The Tribology Handbook

P. 33

A5 Dry rubbing bearings

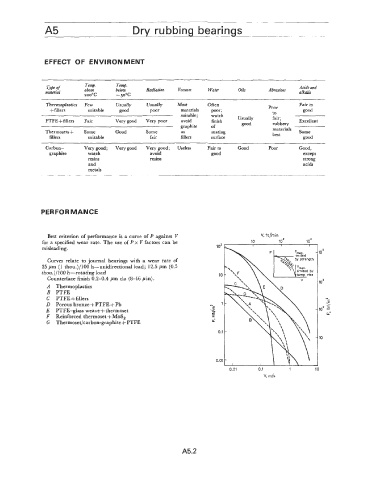

EFFECT OF ENVIRONMENT

Tmp. Temp.

GPe Pf aboue below Radiation Vacuum Water Oils Abrasives $$Td

matmal

200% - 50’C

Thermoplastics Few Usually Usually Most Often Poor Fair to

+fillers suitable good poor materials poor; good

suitable; watch to

fair ;

PTFE+fillen Fair Very good Very poor avoid finish Usually rubbery Excellent

graphite of good materials

Thermosets+ Some Good Some as mating Some

fillers suitable fair fillers surface best good

Carbon- Very good; Very good Very good; Useless Fair to Good Poor Good,

graphite watch avoid good except

resins resins strong

and acids

metals

PERFORMANCE

Best criterion of performance is a curve of P against V V. ftfrnin

for a specified wear rate. The use of PX V factors can be 10 lo2 10’

misleading. lo2

Curves relate to journal bearings with a wear rate of

25 pm (1 thou.)/100 h-unidirectional load; 12.5 pm (0.5

thou.)/100 h-rotating load 10

Counterface finish 0.2-0.4 pm cla (8-16 pin).

A Thermoplastics

B PTFE

C PTFE +fillers

D Porous bronze + PTFE + Pb

E PTFGglass weave+ thermoset

F Reinforced thermoset+ MoS,

G Thermoset/carbon-graphite +PTFE

0.1

0.01

0.01 0.1 1 10

V, mls

A5.2