Page 31 - The Tribology Handbook

P. 31

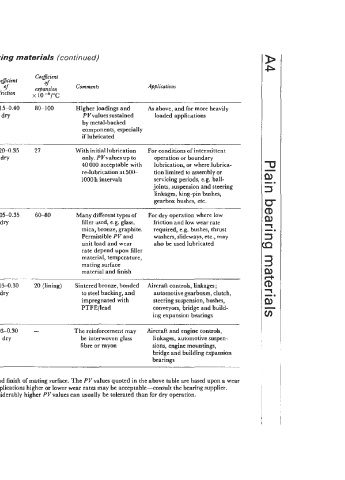

Characteristics of rubbing bearing materials (continued)

Maximum P loadinn PV value Coejicient

Material Maximum Coejicient of

of

Ibf/in2 MN/m2 temperature expansion Comments Applications

Ibf/in2 MN/rn2 xftlmin xm/s “C friction -610c

Therrno-plastic 1500-2000 10-14 1000-3000 0.035-0.1 1 100 0.15-0.40 80-100 Higher loadings and As above, and for more heavily

with filler or dry PVvalues sustained loaded applications

metal-backed by metal-backed

components, especially

if lubricated

~

Thermo-plastic 20 000 140 10 000 0.35 105 0.20-0.35 27 With initial lubrication For conditions of intermittent

with filler dry only. PVvalues up to operation or boundary

bonded to 40 000 acceptable with lubrication, or where lubrica-

metal back re-lubrication at 500- tion limited to assembly or

1000 h intervals servicing periods, e.g. ball-

joints, suspension and steering

linkages, king-pin bushes,

gearbox bushes, etc.

Filled PTFE 1000 7 up to up to 250 0.05-0.35 6MO Many different types of For dry operation where low

10000 0.35 dry filler used, e.g. glass, friction and low wear rate

D mica, bronze, graphite. required, e.g. bushes, thrust

P Permissible PV and washers, slideways, etc., may

Q, unit load and wear also be used lubricated

rate depend upon filler

material, temperature,

mating surface

material and finish

PTFE with 20 000 140 up to up to 280 0.05-0.30 20 (lining) Sintered bronze, bonded Aircraft controls, linkages;

filler, bonded to 50 000 1.75 dry to steel backing, and automotive gearboxes, clutch,

steel backing continu- impregnated with steering suspension, bushes,

ous PTFE/lead conveyors, bridge and build-

rating, ing expansion bearings

Woven PTFE 60000 420 up to up to 250 0.03-0.30 - The reinforcement may Aircraft and engine controls,

reinforced 45 000 1.60 dry be interwoven glass linkages, automotive suspen-

and bonded to continuous fibre or rayon sions, engine mountings,

metal backing rating bridge and building expansion

bearings

Notes: (1) Rates of wear for a given material are influenced by load, speed, temperature, material and finish of mating surface. The PV values quoted in the above table are based upon a wear

rate ofO.001 in (0.025 x 10 -3 rn) per 100 h, where such data are available. For specific applications higher or lower wear rates may be acceptable-consult the bearing supplier.

(2) Where lubrication is provided, either by conventional lubricants or by process fluids, considerably higher PVvalues can usually be tolerated than for dry operation.