Page 37 - The Tribology Handbook

P. 37

A6 Porous meta I beari ncls

i

LIMITING

*/-I

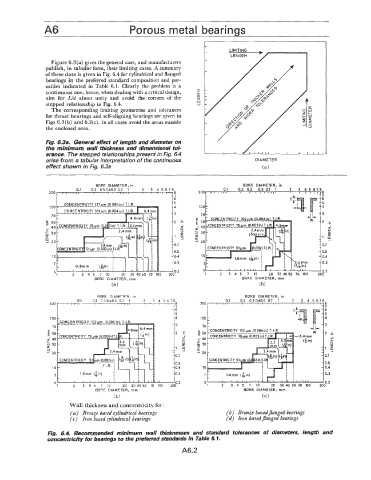

Figure 6.3(a) gives the general case, and manufacturers LENGTH

publish, in tabular form, their limiting cases. A summary

of these data is given in Fig. 6.4 for cylindrical and flanged

bearings in the preferred standard composition and por-

osities indicated in Table 6.1. Clearly the problem is a

continuous one, hence, when dealing with a critical design, r.-

r-

aim for Ud about unity and avoid the corners of the $ I

stepped relationship in Fig. 6.4.

The corresponding limiting geometries and tolerances

for thrust bearings and self-alipning bearings are given in

Figs 6.3(b) and 6.3(c). In all cases avoid the areas outside

the enclosed area.

-/

Fig. 6.3a. General effect of length and diameter on

the minimum wall thickness and dimensional tol-

erance. The stepped relationships present in Fig. 6.4 , I I I I , , ,

arise from a tabular interpretation of the continuous DIAMETER

effect shown in Fig. 6.3a (a)

BORE DIAMETER, in

0.1 0.2 0.3 0.5 0.7 1 2 3 4 5 6 7

:z

200 I I 1 1 . I II 8 2001. I I I ,I I I , , , , I I I Ill

-5

100 -4

70 -3 3

'E 50 - 2 .E 2 .c

- 40 Er f

I:

$ 30 2

z I1 F! 1;

w

J 20 - 0.7 0.7

- 0.5 0.5

10 - 0.4 0.4

- 0.3

7 0.3

5 0.2

1 2 3 4 5 7 10 20 30 4050 70 100 200

BORE DIAMETER, mm BORE DIAMETER, mrn

(a) (b)

BORE DIAMETER, in BORE DIAMETER, in

0.1 0.2 0.3 0.40.5 0.7 1 2 3 4 5678 0.1 0.2 0.3 0.40.5 0.7 1 2 3 4 5 6 7 8

' 'Jt 2OOr I t I II I

-6

-5

-4 100

-3

70

-2 .5 50

r =- 40

+

z 30

a

z

W

2 20

10

1.6mm [kir.) I 0.3

7 I 7

I I

,I, ,I _li 5 "9

51 2 3 4 5 7 10 20 30 40 50 70 100 1 2 3 4 5 7 10 20 30 40 50 70 100 ZOO".&

BORE DIAMETER, mm BORE DIAMETER, rnm

(C) (d i

Wall thickness and concentricity for:

(a) Bronze based cylindrical bearings (b) Bronze basedflanged bearings

(c) Iron based rylindrical bearings (d) hon based flanged bearirigs

Fig. 6.4. Recommended minimum wall thicknesses and standard tolerances of diameters, length and

concentricity for bearings to the preferred standards in Table 6.1.

A6.2