Page 42 - The Tribology Handbook

P. 42

Porous metal bearings A6

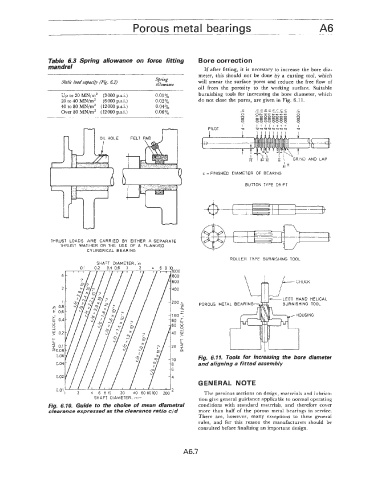

Table 6.3 Spring allowance on force fitting Bore correction

mandrel If after fitting, it is necessary to increase the bore dia-

meter, this should not be done by a cutting tool, which

Static load capan9 fF&. 6.2) Spring will smear the surface pores and reduce the free flow of

allowance

oil from the porosity to the working surface. Suitable

Up to 20 MN/m2 (3 000 psi.) 0.01 yo burnishing tools for increasing the bore diameter, which

20 to 40 hdN/mZ (6 000 psi.) 0.02y0 do not close the pores, are given in Fig. 6.1 1.

40 to 80 MN/mZ (12000 psi.) 0.04%

cccccccc

c

Over 80 NN/mZ (12000 p.s.i.) 0.060/, .- . - ._ .- .- . -. - . - . - ..&

0 -0000000 N 0

0

OF-*----- 00000000

N 0

9 99999999 9

I I I Ill+++ I

PILOT v Ul3l3V~UUW v

IN0 AND LAP

BR

d = FINISHED DIAMETER OF BEARING

BUTTON TYPE DRIFT

THRUST LOADS ARE CARRIED BY EITHER A SEPARATE

THRUST WASHER OR THE USE OF A FLANGED

CYLINDRICAL BEARING

ROLLER TYPE BURNISHING TOOL

SHAFT DIAMETER. in

CHUCK

LEE1 HAND HELICAL

POROUS

Fig. 6.11. Tools for increasing the bore diameter

and aligning a fitted assembly

GENERAL NOTE

u.u I

1 2 4 6 810 20 40 6080100 200 The previous sections on design, materials and lubrica-

SHAFT DIAMETER. mm tion give general guidance applicable to normal operating

Fig. 6.10. Guide to the choice of mean diametral conditions with standard materials, and therefore cover

clearance expressed as the clearance ratio c jd more than half of the porous metal bearings in service.

There are, however, many exceptions to these general

rules, and for this reason the manufacturers should be

consulted before finalising an important design.

A6.7