Page 45 - The Tribology Handbook

P. 45

A7 Grease, wick and drip fed journal bearings

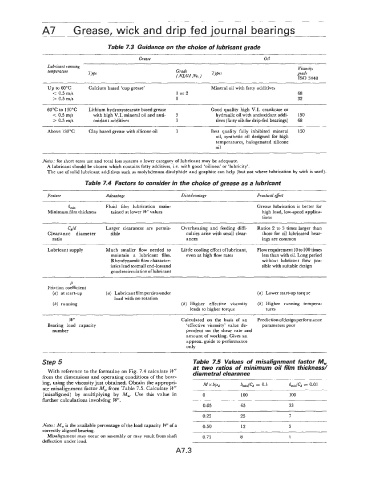

Table 7.3 Guidance on the choice of lubricant grade

Grease Oil

Lubricant running Viscosi[v

temperature Grade grade

Type (NLGI No.) 7ypes

IS0 3448

~

Up to 60°C Calcium based ‘cup grease’ Mineral oil with fatty additives

< 0.5 m/s 1 or2 68

> 0.5 m/s 0 32

60°C to 130°C Lithium hydroxystearate based grease Good quality high V.I. crankcase or

< 0.5 m/s with high V.I. mineral oil and anti- 3 hydraulic oil with antioxidant addi- 150

> 0.5 m/s oxidant additives 3 tives (fatty oils for drip-fed bearings) 68

Above 130°C Clay based grease with silicone oil 3 Best quality fully inhibited mineral 150

oil, synthetic oil designed for high

temperatures, halogenated silicone

oil

Notes; for short term use and total loss systems a lower category of lubricant may be adequate.

A lubricant should be chosen which contains fatty additives, i.e. with good ‘oiliness’ or ‘lubricity’.

The use of solid lubricant additives such as molybdenum disulphide and graphite can help (but not where lubrication by wick is used).

Table 7.4 Factors to consider in the choice of grease as a lubricant

Feature Advantqge Disadvantage Practical efect

kin Fluid film lubrication main- Grease lubrication is better for

Minimum film thickness tained at lower W’ values high load, low-speed applica-

tions

Larger clearances are permis- Overheating and feeding diffi- Ratios 2 to 3 times larger than

Cd/d

Clearance diameter sible culties arise with small clear- those for oil lubricated bear-

ratio ances ings are common

Lubricant supply Much smaller flow needed to Little cooling effect oflubricant, Flowrequirement lOto 100 times

maintain a lubricant film. even at high flow rates less than with oil. Long period

Rheodynamic flow character- without lubricant flow pos-

istics lead tosmall end-loss and sible with suitable design

good recirculationof lubricant

Ir

Friction coefficient

(a) at start-up (a) Lubricant film persist sunder (a) Lower start-up torque

load with no rotation

(b) running (b) Higher effective viscosity (b) Higher running tempera-

leads to higher torque tures

w Calculated on the basis of an Predictionofdesign performance

Bearing load capacity ‘effective viscosity’ value de- parameters poor

number pendent on the shear rate and

amount of working. Gives an

approx. guide to performance

only

Step 5 Table 7.5 Values of misalignment factor M,

With reference to the formulae on Fig. 7.4 calculate W‘ at two ratios of minimum oil film thickness/

diametral clearance

from the dimensions and operating conditions cf the bear-

ing, using the viscosity just obtained. Obtain the appropri- M x bled hmi& = 0.1 h,,/Cd = 0.01

ate misalignment factor M, from Table 7.5. Calculate W’

(misaligned) by multiplying by M,. Use this value in 0 100 100

further calculations involving W‘. -____

0.05 65 33

0.25 25 7

Notes: M, is the available percentage of the load capacity W’ of a 0.50 12 3

correctly aligned bearing.

Misalignment may occur on assembly or may result from shaft 0.75 8 1

deflection under load.

A7.3