Page 40 - The Tribology Handbook

P. 40

LUBRICATION

FELT

As a general recommendation, the oil in the pores should

be replenished every 1000 hours of use or every year,

whichever is the sooner. However, the data in Fig. 6.5

porosity bearings should be replenished more frequently. *---+

should be used to modify this general recommendation. Low

Bearings running submerged or receiving oil-splash will

not require replenishment. See the notes in Table 6.1 about

compositions which are more tolerant to oil starvation.

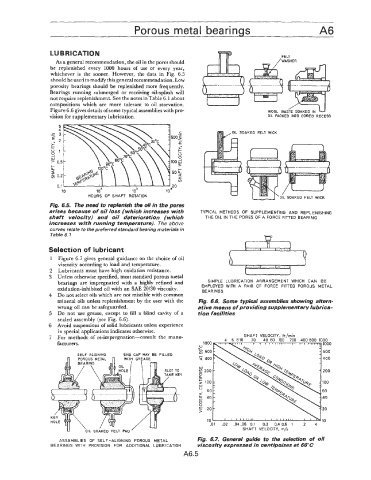

Figure 6.6 gives details of some typical assemblies with pro-

vision for supplementary lubrication. OIL PACKED INTO CORED RECESS

)AKED FELT WICK

n

10 lo2 10’ lo4

HOURS OF SHAFT ROTATION

Fig. 6.5. The need to replenish the oil in the pores

arises because of oil loss (which increases with TYPICAL METHODS OF SUPPLEMENTING AND REPLENISHING

shaft velocity) and oil deterioration (which THE OIL IN THE PORES OF A FORCE FITTED BEARING

increases with running temperature). The above

curves relate to the preferred standard bearing materials in

Table 6.1

Selection of lubricant

Figure 6.7 gives general guidance on the choice of oil

viscosity according to load and temperature.

Lubricants must have high oxidation resistance.

Unless otherwise specified, most standard porous metal

bearings axe impregnated with a highly refined and SIMPLE LUBRICATION ARRANGEMENT WHICH CAN BE

oxidation-inhibited oil with an SAE 20130 viscosity. EMPLOYED WITH A PAIR OF FORCE FITTED POROUS METAL

BEARINGS

Do not select oils which are not miscible with common

mineral oils unless replenishment by the user with the Fig, 6.6. Some typical assemblies showing altern-

wrong oil can be safeguarded. ative means of providing suppjementary lubrica-

Do not use grease, except to fill a blind cavity of a tion facilities

sealed assembly (see Fig. 6.6).

Avoid suspensions of solid lubricants unless experience

in special applications indicates otherwise.

For methods of re-impregnation-consult the manu- 4 6 810 SHAFT VELOCITY, fl/rnin

20

40 60 100 200 400 600

facturers. 1000

V

600

SELF ALIGNING

END CAP MAY BE FILLED

n POROUS METAL n WITH GREASE z 400 4 400

w

v, 200

0

a

s 100

W

V

- 60

5

’” 20 20

>

I I I I I It11 10

.01 .02 .04 .06 0.1 0.2 0.4 0.6 1 2 4

SHAFT VELOCITY, m/s

blL SOAKED FELT PAD’

ASSEMBLIES OF SELF-ALIGNING POROUS METAL Fig. 6.7. General guide to the selection of oil

BEARINGS WITH PROVISION FOR ADDITIONAL LUBRICATION viscosity expressed in centipoises at 60’C

A6.5