Page 49 - The Tribology Handbook

P. 49

A7 Grease, wick and drip fed journal bearings

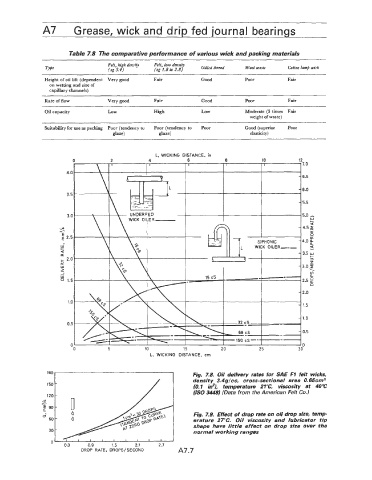

Table 7.8 The comparative performance of various wick and packing materials

Felt, high densitv Felt, low dmig

TVPe (sg 3.4) (sg 1.8 to 2.8) Gilled thread Wool waste Cotton lamp wick

Height of oil lift (dependent Very good Fair Good Poor Fair

on wetting and size of

capillary channels)

Rate of flow Very good Fair Good Poor Fair

Oil capacity Low High Low Moderate (3 times Fair

weight of waste)

Suitability for use as packing Poor (tendency to Poor (tendency to Poor Good (superior Poor

glaze) glaze) elasticity)

4.0

3.5

3.0

$-

E 2.5

W

2

E

> 2.0

a:

W

2

1

W

1.5

1 .O

0.5

0

0 5 10 15 20 25 30-

L, WlCKlNG DISTANCE, crn

150 c Fig. 7.8. Oil delivery rates for SAE F1 feEt wicks,

density 3.4gl cc. cross-sectional area 0.65cm2

120 1 (0.1 id), temperature 21°C, viscosity at 40°C

(IS0 3448) (Data from the American Felt Co.)

n

Fig. 7.9. Effect of drop rate on oil drop size, temp-

erature 2PC. Oil viscosity and lubricator tip

shape have little effect on drop size over the

normal working ranges

0.3 0.9 1.5 2.1 2 .?

DROP RATE, DROPS/SECOND A7.7