Page 295 - The Tribology Handbook

P. 295

B27 Soft piston seals

SELECTION AND DESIGN

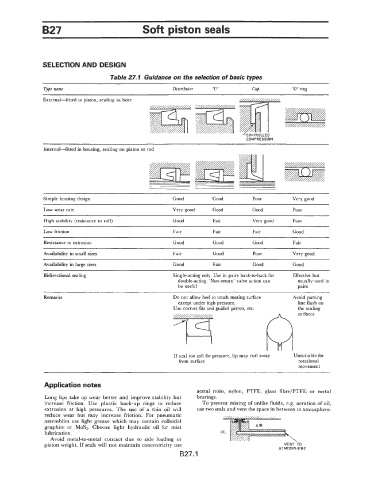

Table 27.1 Guidance on the selection of basic types

l&e name Distributor ‘u’ CUP ‘0’ rinz

External-fitted to piston, sealing in bore

COMPRESSION

Internal-fitted in housing, sealing on piston or rod

Simple housing design Good Good Poor Very good

Low wear rate Very good Good Good Poor

High stability (resistance to roll) Good Fair Very good Po01

Low friction Fair Fair Fair Good

Resistance to extrusion Good Good Good Fair

Availability in small sizes Fair Good Poor Very good

Availability in large sizes Good Fair Good Good

Bidirectional sealing Single-acting only. Use in pairs back-to-back for Effective but

double-acting. ‘Non-return’ valve action can usually used in

be useful pairs

Remarks Do not allow heel to touch mating surface Avoid parting

except under high pressure. line flash on

Use correct fits and guided piston, etc. the sealing

If seal too soft for pressure, lip may curl away Unsuitable for

from surface rotational

movement

Application notes

acetal resin, nylon, PTFE, glass fibre/PTFE or metal

Long lips take up wear better and improve stability but bearings.

increase friction. Use plastic back-up rings to reduce To prevent mixing of unlike fluids, e.g. aeration of oil,

extrusion at high pressures. The use of a thin oil will use two seals and vent the space in between to atmosphere.

reduce wear but may increase friction. For pneumatic

assemblies use light grease which may contain colloidal

graphite or MoS2. Choose light hydraulic oil for mist

lubrication.

Avoid metal-to-metal contact due to side loading or

piston weight. If seals will not maintain concentricity use VENT TO

ATMOSPHERE

B27.1