Page 296 - The Tribology Handbook

P. 296

Soft piston seals B27

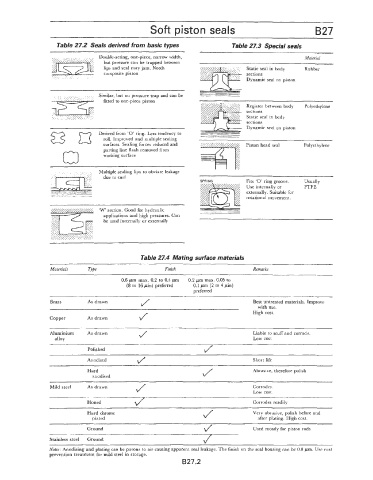

Table 27.2 Seals derived from basic types Table 27.3 Special seals

~~

Double-acting, one-piece, narrow width, Material

but preswre can be trapped between

lips and seal may jam. Needs Rubber

composire piston

Dynamic seal on piston

Similar, but no pressure trap and can be

fitted to one-piece piston

‘\“‘ Register between body Polyethylene

sections

Static seal in body

sections

Dynamic seal on piston

Derived from ‘0’ ring. Less tendency to

roll. Improved and multiple sealing

surfaces. Sealing forces reduced and Piston head seal Polyethylene

parting line flash removed from

working surface

Multiple sealing lips to obviate leakage

due to curl

SPRING Fits ‘0’ ring groove. Usually

Use internally or F’TFE

externally. Suitable for

_. -. .

rotational movement.

~

e~

‘W’ section. Good for hydraulic

applications and high pressures. Can

be used internally or externally

Table 27.4 Mating surface materials

Materials ryPe Finish Remarks

0.6 pm max. 0.2 to 0.4 pm 0.2 pm rnax. 0.05 to

(8 to 16 pin) preferred 0.1 prn (2 to 4 ,pin)

preferred

Brass As drawn Best untreated materials. Improve

J with use.

Copper As drawn J High cost.

Aluminium As drawn J Liable to SCUE and corrode.

alloy Low cost

Polished J

Anodised / Short life

Hard / Abrasive, therefore polish

anodised

J Low cost.

Mild steel As drawn Corrodes.

Honed Corrodes readily

Hard chrome J Very abrasive, polish before and

plated after plating. High cost.

d

Ground Used mostly for piston rods

~~

Stainless steel Ground J

Notes: Anodising and plating can be porous to air causing apparent seal leakage. The finish on the seal housing can be 0.8 pm. Use rust

prevention treatment for mild steel in storage.

B27.2