Page 291 - The Tribology Handbook

P. 291

_______~

B26 Mechanical piston rod packinqs

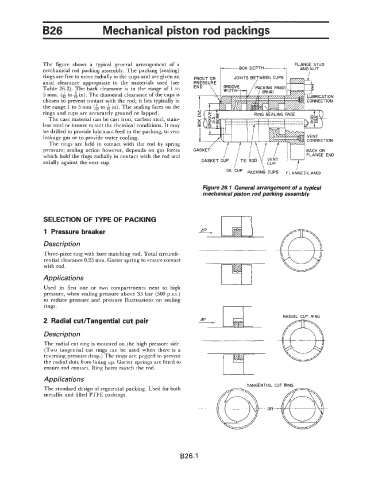

The figure shows a typical general arrangement of a FLANGE STUD

mechanical rod packing assembly. The packing (sealing)

rings are free to move radially in the cups and are given an

axial clearance appropriate to the materials used (see PRESS

Table 26.2). The back clearance is in the range of 1 to END

5 mm. (& to in). The diametral clearance of the cups is

chosen to prevent contact with the rod; it lies typically in

the range 1 to 5 mm (A to 6 in). The sealing faces on the

rings and cups are accurately ground or lapped.

The case material can be cast iron, carbon steel, stain-

less steel or bronze to suit the chemical conditions. It may

be drilled to provide lubricant feed to the packing, to vent

leakage gas or to provide water cooling.

The rings are held in contact with the rod by spring CONNECTION

pressure; sealing action however, depends on gas forces GASKE

which hold the rings radially in contact with the rod and

axially against the next cup.

Figure 26.1 General arrangement of a typical

mechanical piston rod packing assembly

SELECTION OF TYPE OF PACKING

1 Pressure breaker

Description

_~._______. .

Three-piece ring with bore matching rod. Total circumfe-

rential clearance 0.25 mm. Garter spring to ensure contact

with rod.

Applications

Used in first one or two compartments next to high

pressure, when sealing pressure above 35 bar (500 psi)

to reduce pressure and pressure fluctuations on sealing

rings.

RADIAL CUT RING

2 Radial cut/Tangential cut pair

Description

The radial cut ring is mounted on the high pressure side.

(Two tangential cut rings can be used when there is a

reversing pressure drop.) The rings are pegged to prevent

the radial slots from lining up. Garter springs are fitted to

ensure rod contact. Ring bores match the rod.

Applications

TANGENT 'IAL

The standard design of segmental packing. Used for both

metallic and filled PTFE packings.

OR

B26.1