Page 317 - The Tribology Handbook

P. 317

Greases c4

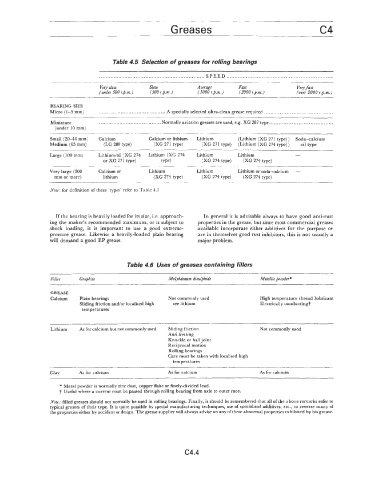

Table 4.5 Selection of greases for rolling bearings

.................................................................. SPEED ..................................................................

Vev slow Slow Average Fast Very fast

(under 500 r.p.m.) (500 7.p.m.) (1000 7.p.m.) (2000 r.p.m.) (over 2000 7.p.m.)

BEARING SIZE

Micro (1-5 mmi) .......................................... A specially selected ultra-clean grease required ..........................................

-

~~

Miniature ....................................... Normally aviation greases are used, e.g. XG 287 type .......................................

(under 10 mm)

Small (20-40 mim) Calcium Calcium or lithium Lithium (Lithium (XC 271 type)) Sodaxalcium

Medium (65 mm) (LG 280 type) (XG 271 type) (XG 271 type) (Lithium (XG 274 type)) oil type

Large (100 mm) Lithium/oil (XG 274 Lithium (XG 274 Lithium Lithium -

or XG 271 type) type) (XG 274 type) (XG 274 type)

Very large (200 Calcium or Lithium Lithium Lithium or soda-calciurn -

mm or more) lithium (XG 274 type) (XG 274 type) (XG 274 type)

____

Note for definiiion of these ‘types’ refer to Table 4 I

If the bearing is heavily loaded for its size, i.e. approach- In general it is advisable always to have good anti-rust

ing the maker’s recommended maximum, or is subject to properties in the grease, but since most commercial greases

shock loading, it is important to use a good extreme- available incorporate either additives for the purpose or

pressure grease. Likewise a heavily-loaded plain bearing are in themselves good rust inhibitors, this is not usually a

will demand a good EP grease. major problem.

Table 4.6 Uses of greases containing fillers

Filler Graphite Molybdenum disulphide Metallic powder*

GREASE

Calcium Plain bearings Not commonly used High temperature thread lubricant

Sliding friction andior localised high see lithium Electrically conducting?

i emperatures

Lithium As for calcium but not commonly used Sliding friction Not commonly used

Anti fretting

Knuckle or ball joint

Reciprocal motion

Rolling bearings

Care must be taken with localised high

temperatures

Clay As for calcium As for calcium As for calcium

* Metal powder is normally zinc dust, copper flake or finely-divided lead.

t Useful where a current must be passed through rolling bearing from axle to outer race.

Note: filled greases should not normally be used in rolling bearings. Finally, it should be remembered.that all of the above remarks refer to

typical greases of their type. It is quite possible by special manufacturing techniques, use of specialised additives, etc., to reverse many of

the properties eiiher by accident or design. The grease supplier will always advise on any ofthese abnormal properties exhibited by his grease.

c4.4