Page 320 - The Tribology Handbook

P. 320

c5 Solid lubricants and coatinas

D BONDED COATINGS a

MoS, resin coatings show performance trends broadly similar to those FAILURE Z-

0

for burnished films but there is less dependence of wear life upon relative i- u

humidity. K

LL

Both the coefficient of friction and the wear rate of the coating vary with E U

0

z

time. W c

w

3 u

Laboratory testing is frequently used to rate different coatings for particular I L

W

applications. 'The most common tests are: LL

0

0

TIME

6

+ c

N W

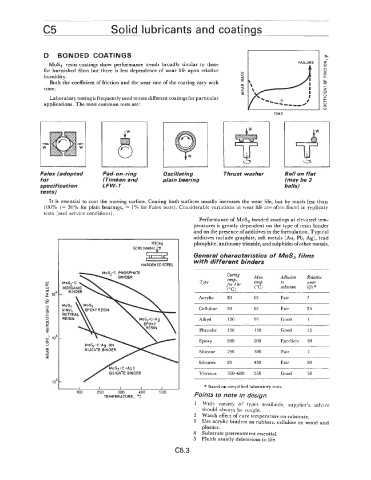

Falex (adopted Pad-on-ring Oscillating Thrust washer Ball on flat

for (Timken and plain bearing (may be 3

specification LFW-1 balls)

tests)

It is essential to coat the moving surface. Coating both surfaces usually increases the wear life, but by much less than

100% (& 30% for plain bearings, 1% for Falex tests). Considerable variations in wear life are often found in replicate

tests (and service conditions).

Performance of MoS, bonded coatings at elevated tem-

peratures is greatly dependent on the type of resin binder

and on the presence of additives in the formulation. Typical

additives include graphite, soft metals (Au, Pb, Ag), lead

phosphite, antimony trioxide, and sulphides ofother metals.

SOREVIMIN

General characteristics of MoS, films

with different binders

HARDENED STEEL

Curing Max. Adhesion Relatiue

temp.

irype for Ihr to wear

l$e *

("CI ("C) substrate

Acrylic 20 65 Fair 7

MOS2 \ \ MOS?

\\EPOXYRESIN \ 1\ Cellulose 20 65 Fair 25

Alkyd 120 95 Good 1

Phenolic 150 150 Good 75

Epoxy 200 200 Excellent 18

SILICATE BINDER Silicone 250 300 Fair 7

Silicates 20 450 Fair 50

SILICATE BINDER Vitreous 300-600 550 Good 50

* Based on simplified laboratory tests.

I I I I I

100 200 300 400 500 Points to note in design

TEMPERATURE, OC

1 Wide variety of types available; supplier's advice

should always be sought.

2 Watch effect of cure temperature on substrate.

3 Use acrylic binders on rubbers, cellulose on wood and

plastics.

4 Substrate pretreatment essential.

5 Fluids usually deleterious to life.

c5.3