Page 318 - The Tribology Handbook

P. 318

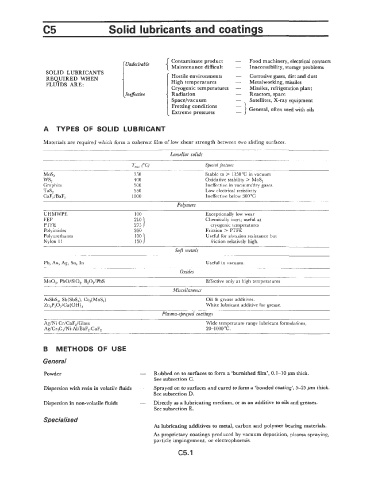

e5 Solid lubricants and coatings

Contaminate product - Food machinery, electrical contacts

Undesirable Maintenance difficult - Inaccessibility, storage problems

SOLID LUBRICANTS Hostile environments - Corrosive gases, dirt and dust

REQUIRED WHEN

FLUIDS ARE: High temperatures - Metalworking, missiles

Cryogenic temperatures - Missiles, refrigeration plant

I Ineffective Radiation - Reactors, space

I Spacefvacuum - . Satellites, X-ray equipment

Fretting conditions }

I Extreme pressures 1 General, often used with oils

A TYPES OF SOLID LUBRICANT

Materials are required which form a coherent film of low shear strength between two sliding surfaces

Lamellar solids

Special features

MoS, 350 Stable to > 1150°C in vacuum

WS, 400 Oxidative stability > MoS,

Graphite 500 Ineffective in vacuum/dry gases

TaS, 550 Low electrical resistivity

CaF,/BaF, 1000 Ineffective below 300 "C

Polymers

UHMWPE 100 Exceptionally low wear

FEP 2 75 1 Chemically inert; useful at

PTFE 210 cryogenic temperatures

Polyimides 300 Friction > PTFE

Polyurethanes 150 I Useful for abrasion resistance but

Nylon 11 loo friction relatively high.

Soft metals

Pb, Au, Ag, Sn, In Useful in vacuum.

Oxides

MOO,, PbO/SiO,, B,O,/PbS Effective only at high temperatures

Miscellaneous

AsSbS,, Sb(SbS,), Ce,(MoS,) Oil & grease additives.

Zn,P,O,/Ca(OH), White lubricant additive for grease.

Plasma-sprayed coatings

Ag/Ni-Cr/CaF,/Glass Wide temperature range lubricant formulations,

Ag/Cr,C,/Ni-AI/BaF,-CaF, 20-1 000 "C.

B METHODS OF USE

General

Powder - Rubbed on to surfaces to form a 'burnished film', 0.1-10 pm thick.

See subsection C.

Dispersion with resin in volatile fluids - Sprayed on to surfaces and cured to form a 'bonded coating', 5-25 pm thick.

See subsection D.

Dispersion in non-volatile fluids - Directly as a lubricating medium, or as an additive to oils and greases.

See subsection E.

Specialised

As lubricating additives to metal, carbon and polymer bearing materials.

As proprietary coatings produced by vacuum deposition, plasma spraying,

particle impingement, or electrophoresis.

C5.1