Page 119 - Welding of Aluminium and its Alloys

P. 119

104 The welding of aluminium and its alloys

RUNS FILLER SPEED

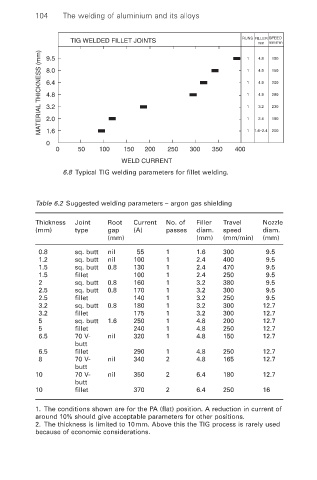

TIG WELDED FILLET JOINTS 1 mm mm/min

MATERIAL THICKNESS (mm) 8.0 1 1 1 1 4.8 150

9.5

4.8

150

6.4

200

4.8

4.8

280

4.8

3.2

3.2

230

2.0

2.4

200

1.6

0 1 1 1.6–2.4 190

0 50 100 150 200 250 300 350 400

WELD CURRENT

6.8 Typical TIG welding parameters for fillet welding.

Table 6.2 Suggested welding parameters – argon gas shielding

Thickness Joint Root Current No. of Filler Travel Nozzle

(mm) type gap (A) passes diam. speed diam.

(mm) (mm) (mm/min) (mm)

0.8 sq. butt nil 55 1 1.6 300 9.5

1.2 sq. butt nil 100 1 2.4 400 9.5

1.5 sq. butt 0.8 130 1 2.4 470 9.5

1.5 fillet 100 1 2.4 250 9.5

2 sq. butt 0.8 160 1 3.2 380 9.5

2.5 sq. butt 0.8 170 1 3.2 300 9.5

2.5 fillet 140 1 3.2 250 9.5

3.2 sq. butt 0.8 180 1 3.2 300 12.7

3.2 fillet 175 1 3.2 300 12.7

5 sq. butt 1.6 250 1 4.8 200 12.7

5 fillet 240 1 4.8 250 12.7

6.5 70 V- nil 320 1 4.8 150 12.7

butt

6.5 fillet 290 1 4.8 250 12.7

8 70 V- nil 340 2 4.8 165 12.7

butt

10 70 V- nil 350 2 6.4 180 12.7

butt

10 fillet 370 2 6.4 250 16

1. The conditions shown are for the PA (flat) position. A reduction in current of

around 10% should give acceptable parameters for other positions.

2. The thickness is limited to 10mm. Above this the TIG process is rarely used

because of economic considerations.