Page 120 - Welding of Aluminium and its Alloys

P. 120

TIG welding 105

(a)

(b)

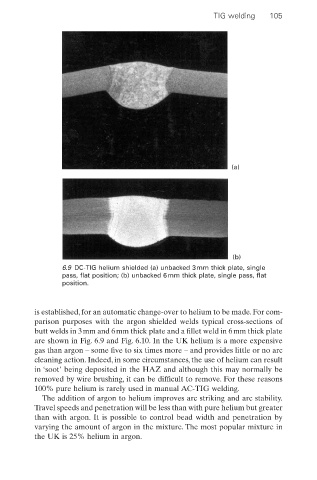

6.9 DC-TIG helium shielded (a) unbacked 3mm thick plate, single

pass, flat position; (b) unbacked 6mm thick plate, single pass, flat

position.

is established, for an automatic change-over to helium to be made. For com-

parison purposes with the argon shielded welds typical cross-sections of

butt welds in 3mm and 6mm thick plate and a fillet weld in 6mm thick plate

are shown in Fig. 6.9 and Fig. 6.10. In the UK helium is a more expensive

gas than argon – some five to six times more – and provides little or no arc

cleaning action. Indeed, in some circumstances, the use of helium can result

in ‘soot’ being deposited in the HAZ and although this may normally be

removed by wire brushing, it can be difficult to remove. For these reasons

100% pure helium is rarely used in manual AC-TIG welding.

The addition of argon to helium improves arc striking and arc stability.

Travel speeds and penetration will be less than with pure helium but greater

than with argon. It is possible to control bead width and penetration by

varying the amount of argon in the mixture. The most popular mixture in

the UK is 25% helium in argon.