Page 125 - Welding of Aluminium and its Alloys

P. 125

110 The welding of aluminium and its alloys

filler wire

80°

10 to 20°

Travel direction

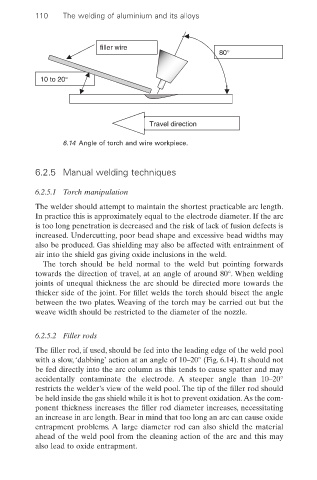

6.14 Angle of torch and wire workpiece.

6.2.5 Manual welding techniques

6.2.5.1 Torch manipulation

The welder should attempt to maintain the shortest practicable arc length.

In practice this is approximately equal to the electrode diameter. If the arc

is too long penetration is decreased and the risk of lack of fusion defects is

increased. Undercutting, poor bead shape and excessive bead widths may

also be produced. Gas shielding may also be affected with entrainment of

air into the shield gas giving oxide inclusions in the weld.

The torch should be held normal to the weld but pointing forwards

towards the direction of travel, at an angle of around 80°. When welding

joints of unequal thickness the arc should be directed more towards the

thicker side of the joint. For fillet welds the torch should bisect the angle

between the two plates. Weaving of the torch may be carried out but the

weave width should be restricted to the diameter of the nozzle.

6.2.5.2 Filler rods

The filler rod, if used, should be fed into the leading edge of the weld pool

with a slow, ‘dabbing’ action at an angle of 10–20° (Fig. 6.14). It should not

be fed directly into the arc column as this tends to cause spatter and may

accidentally contaminate the electrode. A steeper angle than 10–20°

restricts the welder’s view of the weld pool. The tip of the filler rod should

be held inside the gas shield while it is hot to prevent oxidation.As the com-

ponent thickness increases the filler rod diameter increases, necessitating

an increase in arc length. Bear in mind that too long an arc can cause oxide

entrapment problems. A large diameter rod can also shield the material

ahead of the weld pool from the cleaning action of the arc and this may

also lead to oxide entrapment.