Page 134 - Welding of Aluminium and its Alloys

P. 134

MIG welding 119

Small change in voltage

ARC

VOLTAGE

Large change in current

WELDING CURRENT

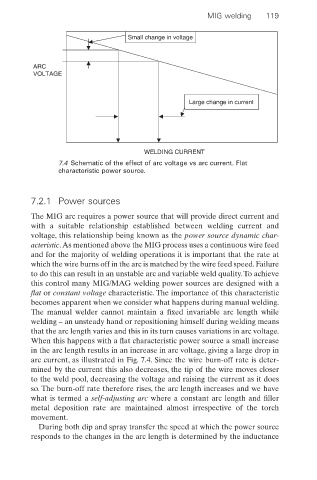

7.4 Schematic of the effect of arc voltage vs arc current. Flat

characteristic power source.

7.2.1 Power sources

The MIG arc requires a power source that will provide direct current and

with a suitable relationship established between welding current and

voltage, this relationship being known as the power source dynamic char-

acteristic.As mentioned above the MIG process uses a continuous wire feed

and for the majority of welding operations it is important that the rate at

which the wire burns off in the arc is matched by the wire feed speed.Failure

to do this can result in an unstable arc and variable weld quality.To achieve

this control many MIG/MAG welding power sources are designed with a

flat or constant voltage characteristic. The importance of this characteristic

becomes apparent when we consider what happens during manual welding.

The manual welder cannot maintain a fixed invariable arc length while

welding – an unsteady hand or repositioning himself during welding means

that the arc length varies and this in its turn causes variations in arc voltage.

When this happens with a flat characteristic power source a small increase

in the arc length results in an increase in arc voltage, giving a large drop in

arc current, as illustrated in Fig. 7.4. Since the wire burn-off rate is deter-

mined by the current this also decreases, the tip of the wire moves closer

to the weld pool, decreasing the voltage and raising the current as it does

so. The burn-off rate therefore rises, the arc length increases and we have

what is termed a self-adjusting arc where a constant arc length and filler

metal deposition rate are maintained almost irrespective of the torch

movement.

During both dip and spray transfer the speed at which the power source

responds to the changes in the arc length is determined by the inductance