Page 135 - Welding of Aluminium and its Alloys

P. 135

120 The welding of aluminium and its alloys

Large change in voltage

ARC

VOLTAGE

Small change in current

WELDING CURRENT

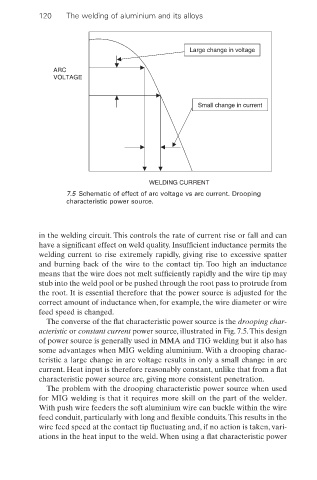

7.5 Schematic of effect of arc voltage vs arc current. Drooping

characteristic power source.

in the welding circuit. This controls the rate of current rise or fall and can

have a significant effect on weld quality. Insufficient inductance permits the

welding current to rise extremely rapidly, giving rise to excessive spatter

and burning back of the wire to the contact tip. Too high an inductance

means that the wire does not melt sufficiently rapidly and the wire tip may

stub into the weld pool or be pushed through the root pass to protrude from

the root. It is essential therefore that the power source is adjusted for the

correct amount of inductance when, for example, the wire diameter or wire

feed speed is changed.

The converse of the flat characteristic power source is the drooping char-

acteristic or constant current power source, illustrated in Fig. 7.5.This design

of power source is generally used in MMA and TIG welding but it also has

some advantages when MIG welding aluminium. With a drooping charac-

teristic a large change in arc voltage results in only a small change in arc

current. Heat input is therefore reasonably constant, unlike that from a flat

characteristic power source arc, giving more consistent penetration.

The problem with the drooping characteristic power source when used

for MIG welding is that it requires more skill on the part of the welder.

With push wire feeders the soft aluminium wire can buckle within the wire

feed conduit, particularly with long and flexible conduits.This results in the

wire feed speed at the contact tip fluctuating and, if no action is taken, vari-

ations in the heat input to the weld. When using a flat characteristic power