Page 168 - Welding of Aluminium and its Alloys

P. 168

Other welding processes 151

'Chevron' weld

Focused bead pattern

laser beam

Weld direction

Molten metal flows

round keyhole and

recombines to form

weld

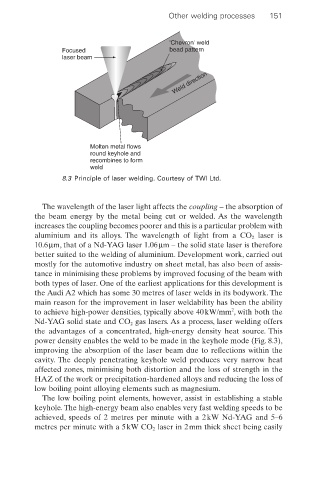

8.3 Principle of laser welding. Courtesy of TWI Ltd.

The wavelength of the laser light affects the coupling – the absorption of

the beam energy by the metal being cut or welded. As the wavelength

increases the coupling becomes poorer and this is a particular problem with

aluminium and its alloys. The wavelength of light from a CO 2 laser is

10.6mm, that of a Nd-YAG laser 1.06mm – the solid state laser is therefore

better suited to the welding of aluminium. Development work, carried out

mostly for the automotive industry on sheet metal, has also been of assis-

tance in minimising these problems by improved focusing of the beam with

both types of laser. One of the earliest applications for this development is

the Audi A2 which has some 30 metres of laser welds in its bodywork. The

main reason for the improvement in laser weldability has been the ability

2

to achieve high-power densities, typically above 40kW/mm , with both the

Nd-YAG solid state and CO 2 gas lasers. As a process, laser welding offers

the advantages of a concentrated, high-energy density heat source. This

power density enables the weld to be made in the keyhole mode (Fig. 8.3),

improving the absorption of the laser beam due to reflections within the

cavity. The deeply penetrating keyhole weld produces very narrow heat

affected zones, minimising both distortion and the loss of strength in the

HAZ of the work or precipitation-hardened alloys and reducing the loss of

low boiling point alloying elements such as magnesium.

The low boiling point elements, however, assist in establishing a stable

keyhole. The high-energy beam also enables very fast welding speeds to be

achieved, speeds of 2 metres per minute with a 2kW Nd-YAG and 5–6

metres per minute with a 5kW CO 2 laser in 2mm thick sheet being easily