Page 165 - Welding of Aluminium and its Alloys

P. 165

148 The welding of aluminium and its alloys

Tungsten electrode

Cooling water

–VE

Plasma gas

Power

source

+VE Nozzle

Shielding gas

Workpiece

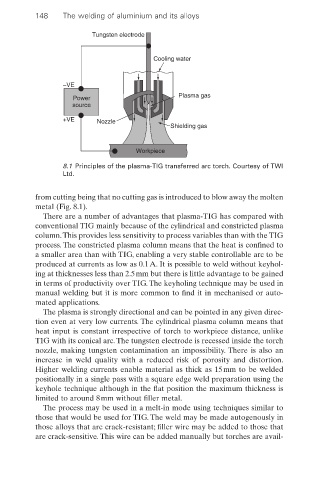

8.1 Principles of the plasma-TIG transferred arc torch. Courtesy of TWI

Ltd.

from cutting being that no cutting gas is introduced to blow away the molten

metal (Fig. 8.1).

There are a number of advantages that plasma-TIG has compared with

conventional TIG mainly because of the cylindrical and constricted plasma

column.This provides less sensitivity to process variables than with the TIG

process. The constricted plasma column means that the heat is confined to

a smaller area than with TIG, enabling a very stable controllable arc to be

produced at currents as low as 0.1A. It is possible to weld without keyhol-

ing at thicknesses less than 2.5mm but there is little advantage to be gained

in terms of productivity over TIG. The keyholing technique may be used in

manual welding but it is more common to find it in mechanised or auto-

mated applications.

The plasma is strongly directional and can be pointed in any given direc-

tion even at very low currents. The cylindrical plasma column means that

heat input is constant irrespective of torch to workpiece distance, unlike

TIG with its conical arc.The tungsten electrode is recessed inside the torch

nozzle, making tungsten contamination an impossibility. There is also an

increase in weld quality with a reduced risk of porosity and distortion.

Higher welding currents enable material as thick as 15mm to be welded

positionally in a single pass with a square edge weld preparation using the

keyhole technique although in the flat position the maximum thickness is

limited to around 8mm without filler metal.

The process may be used in a melt-in mode using techniques similar to

those that would be used for TIG. The weld may be made autogenously in

those alloys that are crack-resistant; filler wire may be added to those that

are crack-sensitive. This wire can be added manually but torches are avail-