Page 175 - Welding of Aluminium and its Alloys

P. 175

158 The welding of aluminium and its alloys

Electron

Electron beam

gun

Vacuum

chamber

Parent Weld

metal metal

Weld

Keyhole Motion of

pool

workpiece

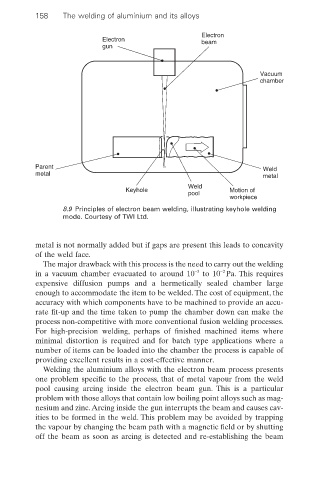

8.9 Principles of electron beam welding, illustrating keyhole welding

mode. Courtesy of TWI Ltd.

metal is not normally added but if gaps are present this leads to concavity

of the weld face.

The major drawback with this process is the need to carry out the welding

-2

in a vacuum chamber evacuated to around 10 -3 to 10 Pa. This requires

expensive diffusion pumps and a hermetically sealed chamber large

enough to accommodate the item to be welded. The cost of equipment, the

accuracy with which components have to be machined to provide an accu-

rate fit-up and the time taken to pump the chamber down can make the

process non-competitive with more conventional fusion welding processes.

For high-precision welding, perhaps of finished machined items where

minimal distortion is required and for batch type applications where a

number of items can be loaded into the chamber the process is capable of

providing excellent results in a cost-effective manner.

Welding the aluminium alloys with the electron beam process presents

one problem specific to the process, that of metal vapour from the weld

pool causing arcing inside the electron beam gun. This is a particular

problem with those alloys that contain low boiling point alloys such as mag-

nesium and zinc.Arcing inside the gun interrupts the beam and causes cav-

ities to be formed in the weld. This problem may be avoided by trapping

the vapour by changing the beam path with a magnetic field or by shutting

off the beam as soon as arcing is detected and re-establishing the beam