Page 180 - Welding of Aluminium and its Alloys

P. 180

Other welding processes 163

Sufficient downward force to

maintain registered contact

Advancing

side of weld Joint

Leading

edge of the

Shoulder rotating tool

Probe

Trailing edge of Retreating side

the rotating tool of weld

8.13 Principle of the friction stir welding process. Courtesy of TWI Ltd.

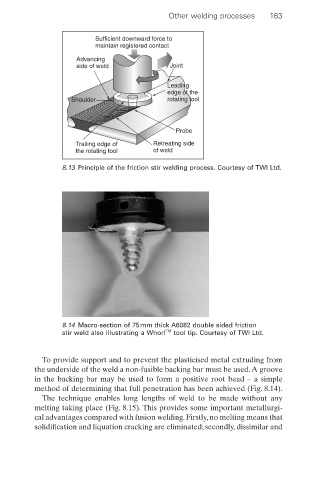

8.14 Macro-section of 75mm thick A6082 double sided friction

stir weld also illustrating a Whorl TM tool tip. Courtesy of TWI Ltd.

To provide support and to prevent the plasticised metal extruding from

the underside of the weld a non-fusible backing bar must be used.A groove

in the backing bar may be used to form a positive root bead – a simple

method of determining that full penetration has been achieved (Fig. 8.14).

The technique enables long lengths of weld to be made without any

melting taking place (Fig. 8.15). This provides some important metallurgi-

cal advantages compared with fusion welding. Firstly, no melting means that

solidification and liquation cracking are eliminated; secondly, dissimilar and