Page 184 - Welding of Aluminium and its Alloys

P. 184

Resistance welding processes 167

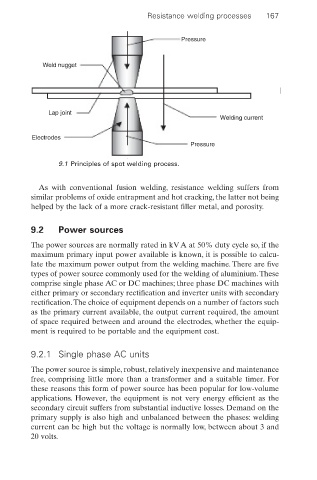

Pressure

Weld nugget

Lap joint

Welding current

Electrodes

Pressure

9.1 Principles of spot welding process.

As with conventional fusion welding, resistance welding suffers from

similar problems of oxide entrapment and hot cracking, the latter not being

helped by the lack of a more crack-resistant filler metal, and porosity.

9.2 Power sources

The power sources are normally rated in kVA at 50% duty cycle so, if the

maximum primary input power available is known, it is possible to calcu-

late the maximum power output from the welding machine. There are five

types of power source commonly used for the welding of aluminium.These

comprise single phase AC or DC machines; three phase DC machines with

either primary or secondary rectification and inverter units with secondary

rectification.The choice of equipment depends on a number of factors such

as the primary current available, the output current required, the amount

of space required between and around the electrodes, whether the equip-

ment is required to be portable and the equipment cost.

9.2.1 Single phase AC units

The power source is simple, robust, relatively inexpensive and maintenance

free, comprising little more than a transformer and a suitable timer. For

these reasons this form of power source has been popular for low-volume

applications. However, the equipment is not very energy efficient as the

secondary circuit suffers from substantial inductive losses. Demand on the

primary supply is also high and unbalanced between the phases: welding

current can be high but the voltage is normally low, between about 3 and

20 volts.