Page 92 - Welding of Aluminium and its Alloys

P. 92

Welding design 81

Actual throat

Reduction in Expected throat

throat

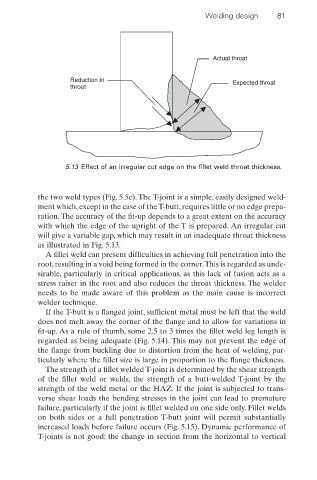

5.13 Effect of an irregular cut edge on the fillet weld throat thickness.

the two weld types (Fig. 5.5c). The T-joint is a simple, easily designed weld-

ment which, except in the case of the T-butt, requires little or no edge prepa-

ration. The accuracy of the fit-up depends to a great extent on the accuracy

with which the edge of the upright of the T is prepared. An irregular cut

will give a variable gap, which may result in an inadequate throat thickness

as illustrated in Fig. 5.13.

A fillet weld can present difficulties in achieving full penetration into the

root,resulting in a void being formed in the corner.This is regarded as unde-

sirable, particularly in critical applications, as this lack of fusion acts as a

stress raiser in the root and also reduces the throat thickness. The welder

needs to be made aware of this problem as the main cause is incorrect

welder technique.

If the T-butt is a flanged joint, sufficient metal must be left that the weld

does not melt away the corner of the flange and to allow for variations in

fit-up. As a rule of thumb, some 2.5 to 3 times the fillet weld leg length is

regarded as being adequate (Fig. 5.14). This may not prevent the edge of

the flange from buckling due to distortion from the heat of welding, par-

ticularly where the fillet size is large in proportion to the flange thickness.

The strength of a fillet welded T-joint is determined by the shear strength

of the fillet weld or welds, the strength of a butt-welded T-joint by the

strength of the weld metal or the HAZ. If the joint is subjected to trans-

verse shear loads the bending stresses in the joint can lead to premature

failure, particularly if the joint is fillet welded on one side only. Fillet welds

on both sides or a full penetration T-butt joint will permit substantially

increased loads before failure occurs (Fig. 5.15). Dynamic performance of

T-joints is not good: the change in section from the horizontal to vertical