Page 96 - Welding of Aluminium and its Alloys

P. 96

Welding design 85

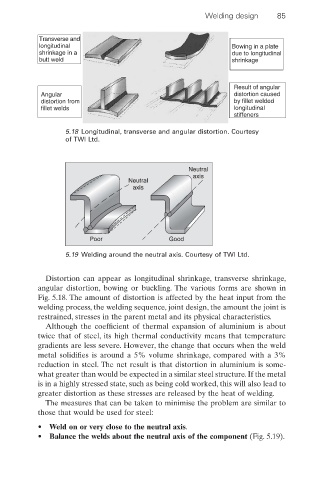

Transverse and

longitudinal Bowing in a plate

shrinkage in a due to longitudinal

butt weld shrinkage

Result of angular

Angular distortion caused

distortion from by fillet welded

fillet welds longitudinal

stiffeners

5.18 Longitudinal, transverse and angular distortion. Courtesy

of TWI Ltd.

Neutral

axis

Neutral

axis

Poor Good

5.19 Welding around the neutral axis. Courtesy of TWI Ltd.

Distortion can appear as longitudinal shrinkage, transverse shrinkage,

angular distortion, bowing or buckling. The various forms are shown in

Fig. 5.18. The amount of distortion is affected by the heat input from the

welding process, the welding sequence, joint design, the amount the joint is

restrained, stresses in the parent metal and its physical characteristics.

Although the coefficient of thermal expansion of aluminium is about

twice that of steel, its high thermal conductivity means that temperature

gradients are less severe. However, the change that occurs when the weld

metal solidifies is around a 5% volume shrinkage, compared with a 3%

reduction in steel. The net result is that distortion in aluminium is some-

what greater than would be expected in a similar steel structure. If the metal

is in a highly stressed state, such as being cold worked, this will also lead to

greater distortion as these stresses are released by the heat of welding.

The measures that can be taken to minimise the problem are similar to

those that would be used for steel:

• Weld on or very close to the neutral axis.

• Balance the welds about the neutral axis of the component (Fig. 5.19).