Page 19 - The engineering of chemical reactions

P. 19

Chapter 1

INTRODUCTION

-

CHEMICAL REACTORS

he chemical reactor is the heart of any chemical process. Chemical processes turn

inexpensive chemicals into valuable ones, and chemical engineers are the only

T people technically trained to understand and handle them. While separation units

are usually the largest components of a chemical process, their purpose is to purify raw

materials before they enter the chemical reactor and to purify products after they leave

the reactor.

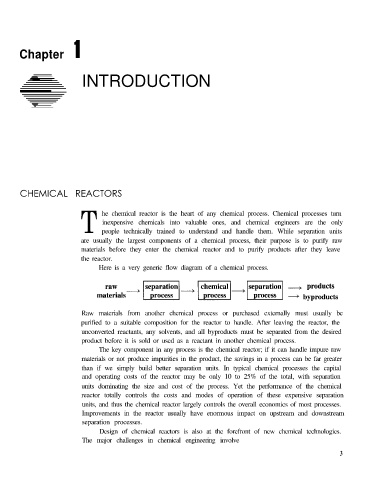

Here is a very generic flow diagram of a chemical process.

Raw materials from another chemical process or purchased externally must usually be

purified to a suitable composition for the reactor to handle. After leaving the reactor, the

unconverted reactants, any solvents, and all byproducts must be separated from the desired

product before it is sold or used as a reactant in another chemical process.

The key component in any process is the chemical reactor; if it can handle impure raw

materials or not produce impurities in the product, the savings in a process can be far greater

than if we simply build better separation units. In typical chemical processes the capital

and operating costs of the reactor may be only 10 to 25% of the total, with separation

units dominating the size and cost of the process. Yet the performance of the chemical

reactor totally controls the costs and modes of operation of these expensive separation

units, and thus the chemical reactor largely controls the overall economics of most processes.

Improvements in the reactor usually have enormous impact on upstream and downstream

separation processes.

Design of chemical reactors is also at the forefront of new chemical technologies.

The major challenges in chemical engineering involve

3