Page 84 - The engineering of chemical reactions

P. 84

68 Reaction Rates, the Batch Reactor, and the Real World

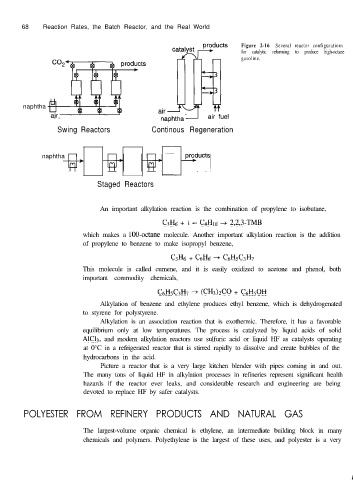

Figure 2-16 Several reactor configurations

for catalytic reforming to produce high-octane

gasoline.

naphtha

Swing Reactors Continous Regeneration

naphtha n

*

Staged Reactors

An important alkylation reaction is the combination of propylene to isobutane,

C3Hs + i - C,HIO -+ 2,2,3-TMB

which makes a loo-octane molecule. Another important alkylation reaction is the addition

of propylene to benzene to make isopropyl benzene,

C3H6 + C& + CrjH&H7

This molecule is called cumene, and it is easily oxidized to acetone and phenol, both

important commodity chemicals,

c&c& -+ (CH&CO + C6H@H

Alkylation of benzene and ethylene produces ethyl benzene, which is dehydrogenated

to styrene for polystyrene.

Alkylation is an association reaction that is exothermic. Therefore, it has a favorable

equilibrium only at low temperatures. The process is catalyzed by liquid acids of solid

AlC13, and modern alkylation reactors use sulfuric acid or liquid HF as catalysts operating

at 0°C in a refrigerated reactor that is stirred rapidly to dissolve and create bubbles of the

hydrocarbons in the acid.

Picture a reactor that is a very large kitchen blender with pipes coming in and out.

The many tons of liquid HF in alkylation processes in refineries represent significant health

hazards if the reactor ever leaks, and considerable research and engineering are being

devoted to replace HF by safer catalysts.

POLYESTER FROM REFINERY PRODUCTS AND NATURAL GAS

The largest-volume organic chemical is ethylene, an intermediate building block in many

chemicals and polymers. Polyethylene is the largest of these uses, and polyester is a very