Page 88 - The engineering of chemical reactions

P. 88

7 2 Reaction Rates, the Batch Reactor, and the Real World

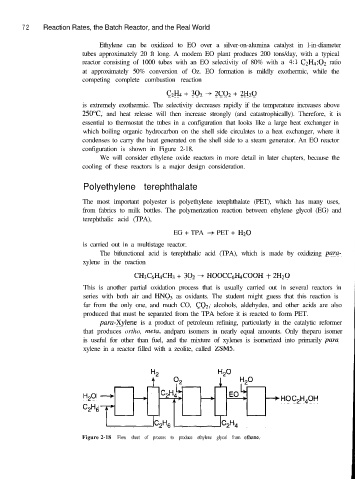

Ethylene can be oxidized to EO over a silver-on-alumina catalyst in l-in-diameter

tubes approximately 20 ft long. A modem EO plant produces 200 tons/day, with a typical

reactor consisting of 1000 tubes with an EO selectivity of 80% with a 4:l C2H4:02 ratio

at approximately 50% conversion of Oz. EO formation is mildly exothermic, while the

competing complete combustion reaction

C2H4 + 302 -+ 2C02 + 2H20

is extremely exothermic. The selectivity decreases rapidly if the temperature increases above

250°C, and heat release will then increase strongly (and catastrophically). Therefore, it is

essential to thermostat the tubes in a configuration that looks like a large heat exchanger in

which boiling organic hydrocarbon on the shell side circulates to a heat exchanger, where it

condenses to carry the heat generated on the shell side to a steam generator. An EO reactor

configuration is shown in Figure 2-18.

We will consider ethylene oxide reactors in more detail in later chapters, because the

cooling of these reactors is a major design consideration.

Polyethylene terephthalate

The most important polyester is polyethylene terephthalate (PET), which has many uses,

from fabrics to milk bottles. The polymerization reaction between ethylene glycol (EG) and

terephthalic acid (TPA),

EG + TPA -+ PET + H20

is carried out in a multistage reactor.

The bifunctional acid is terephthalic acid (TPA), which is made by oxidizing para-

xylene in the reaction

CH3C6H4CH3 + 302 -+ HOOCC&COOH + 2H20

This is another partial oxidation process that is usually carried out in several reactors in

series with both air and HNOs as oxidants. The student might guess that this reaction is

far from the only one, and much CO, COZ, alcohols, aldehydes, and other acids are also

produced that must be separated from the TPA before it is reacted to form PET.

para-Xylene is a product of petroleum refining, particularly in the catalytic reformer

that produces ortho, metu, andparu isomers in nearly equal amounts. Only theparu isomer

is useful for other than fuel, and the mixture of xylenes is isomerized into primarily pm-u

xylene in a reactor filled with a zeolite, called ZSMS.

H2O - - HOC,H,OH

C2H6

Figure 2-18 Flow sheet of process to produce ethylene glycol from e&me.