Page 1022 - The Mechatronics Handbook

P. 1022

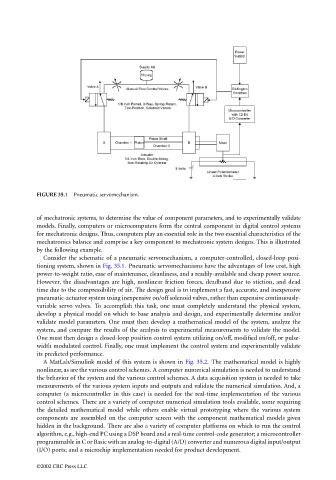

FIGURE 35.1 Pneumatic servomechanism.

of mechatronic systems, to determine the value of component parameters, and to experimentally validate

models. Finally, computers or microcomputers form the central component in digital control systems

for mechatronic designs. Thus, computers play an essential role in the two essential characteristics of the

mechatronics balance and comprise a key component to mechatronic system designs. This is illustrated

by the following example.

Consider the schematic of a pneumatic servomechanism, a computer-controlled, closed-loop posi-

tioning system, shown in Fig. 35.1. Pneumatic servomechanisms have the advantages of low cost, high

power-to-weight ratio, ease of maintenance, cleanliness, and a readily-available and cheap power source.

However, the disadvantages are high, nonlinear friction forces, deadband due to stiction, and dead

time due to the compressibility of air. The design goal is to implement a fast, accurate, and inexpensive

pneumatic-actuator system using inexpensive on/off solenoid valves, rather than expensive continuously-

variable servo valves. To accomplish this task, one must completely understand the physical system,

develop a physical model on which to base analysis and design, and experimentally determine and/or

validate model parameters. One must then develop a mathematical model of the system, analyze the

system, and compare the results of the analysis to experimental measurements to validate the model.

One must then design a closed-loop position control system utilizing on/off, modified on/off, or pulse-

width modulated control. Finally, one must implement the control system and experimentally validate

its predicted performance.

A MatLab/Simulink model of this system is shown in Fig. 35.2. The mathematical model is highly

nonlinear, as are the various control schemes. A computer numerical simulation is needed to understand

the behavior of the system and the various control schemes. A data acquisition system is needed to take

measurements of the various system inputs and outputs and validate the numerical simulation. And, a

computer (a microcontroller in this case) is needed for the real-time implementation of the various

control schemes. There are a variety of computer numerical simulation tools available, some requiring

the detailed mathematical model while others enable virtual prototyping where the various system

components are assembled on the computer screen with the component mathematical models given

hidden in the background. There are also a variety of computer platforms on which to run the control

algorithm, e.g., high-end PC using a DSP board and a real-time control-code generator; a microcontroller

programmable in C or Basic with an analog-to-digital (A/D) converter and numerous digital input/output

(I/O) ports; and a microchip implementation needed for product development.

©2002 CRC Press LLC