Page 1027 - The Mechatronics Handbook

P. 1027

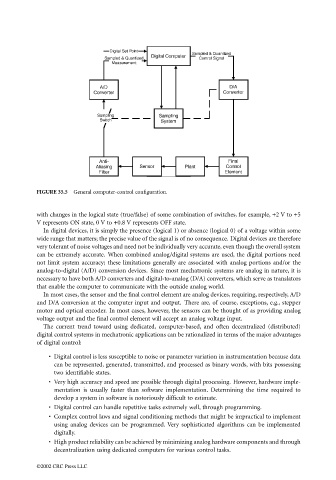

FIGURE 35.5 General computer-control configuration.

with changes in the logical state (true/false) of some combination of switches, for example, +2 V to +5

V represents ON state, 0 V to +0.8 V represents OFF state.

In digital devices, it is simply the presence (logical 1) or absence (logical 0) of a voltage within some

wide range that matters; the precise value of the signal is of no consequence. Digital devices are therefore

very tolerant of noise voltages and need not be individually very accurate, even though the overall system

can be extremely accurate. When combined analog/digital systems are used, the digital portions need

not limit system accuracy; these limitations generally are associated with analog portions and/or the

analog-to-digital (A/D) conversion devices. Since most mechatronic systems are analog in nature, it is

necessary to have both A/D converters and digital-to-analog (D/A) converters, which serve as translators

that enable the computer to communicate with the outside analog world.

In most cases, the sensor and the final control element are analog devices, requiring, respectively, A/D

and D/A conversion at the computer input and output. There are, of course, exceptions, e.g., stepper

motor and optical encoder. In most cases, however, the sensors can be thought of as providing analog

voltage output and the final control element will accept an analog voltage input.

The current trend toward using dedicated, computer-based, and often decentralized (distributed)

digital control systems in mechatronic applications can be rationalized in terms of the major advantages

of digital control:

• Digital control is less susceptible to noise or parameter variation in instrumentation because data

can be represented, generated, transmitted, and processed as binary words, with bits possessing

two identifiable states.

• Very high accuracy and speed are possible through digital processing. However, hardware imple-

mentation is usually faster than software implementation. Determining the time required to

develop a system in software is notoriously difficult to estimate.

• Digital control can handle repetitive tasks extremely well, through programming.

• Complex control laws and signal conditioning methods that might be impractical to implement

using analog devices can be programmed. Very sophisticated algorithms can be implemented

digitally.

• High product reliability can be achieved by minimizing analog hardware components and through

decentralization using dedicated computers for various control tasks.

©2002 CRC Press LLC