Page 193 - The Mechatronics Handbook

P. 193

Valve 1 Valve 2

M

Valve 3

Valve 4

Controller

Valve 5

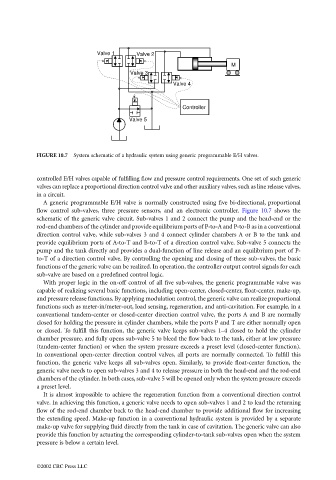

FIGURE 10.7 System schematic of a hydraulic system using generic programmable E/H valves.

controlled E/H valves capable of fulfilling flow and pressure control requirements. One set of such generic

valves can replace a proportional direction control valve and other auxiliary valves, such as line release valves,

in a circuit.

A generic programmable E/H valve is normally constructed using five bi-directional, proportional

flow control sub-valves, three pressure sensors, and an electronic controller. Figure 10.7 shows the

schematic of the generic valve circuit. Sub-valves 1 and 2 connect the pump and the head-end or the

rod-end chambers of the cylinder and provide equilibrium ports of P-to-A and P-to-B as in a conventional

direction control valve, while sub-valves 3 and 4 connect cylinder chambers A or B to the tank and

provide equilibrium ports of A-to-T and B-to-T of a direction control valve. Sub-valve 5 connects the

pump and the tank directly and provides a dual-function of line release and an equilibrium port of P-

to-T of a direction control valve. By controlling the opening and closing of these sub-valves, the basic

functions of the generic valve can be realized. In operation, the controller output control signals for each

sub-valve are based on a predefined control logic.

With proper logic in the on-off control of all five sub-valves, the generic programmable valve was

capable of realizing several basic functions, including open-center, closed-center, float-center, make-up,

and pressure release functions. By applying modulation control, the generic valve can realize proportional

functions such as meter-in/meter-out, load sensing, regeneration, and anti-cavitation. For example, in a

conventional tandem-center or closed-center direction control valve, the ports A and B are normally

closed for holding the pressure in cylinder chambers, while the ports P and T are either normally open

or closed. To fulfill this function, the generic valve keeps sub-valves 1–4 closed to hold the cylinder

chamber pressure, and fully opens sub-valve 5 to bleed the flow back to the tank, either at low pressure

(tandem-center function) or when the system pressure exceeds a preset level (closed-center function).

In conventional open-center direction control valves, all ports are normally connected. To fulfill this

function, the generic valve keeps all sub-valves open. Similarly, to provide float-center function, the

generic valve needs to open sub-valves 3 and 4 to release pressure in both the head-end and the rod-end

chambers of the cylinder. In both cases, sub-valve 5 will be opened only when the system pressure exceeds

a preset level.

It is almost impossible to achieve the regeneration function from a conventional direction control

valve. In achieving this function, a generic valve needs to open sub-valves 1 and 2 to lead the returning

flow of the rod-end chamber back to the head-end chamber to provide additional flow for increasing

the extending speed. Make-up function in a conventional hydraulic system is provided by a separate

make-up valve for supplying fluid directly from the tank in case of cavitation. The generic valve can also

provide this function by actuating the corresponding cylinder-to-tank sub-valves open when the system

pressure is below a certain level.

©2002 CRC Press LLC