Page 103 - Thermal Hydraulics Aspects of Liquid Metal Cooled Nuclear Reactors

P. 103

Rod bundle and pool-type experiments in water serving liquid metal reactors 77

Optics Nd: YAG laser

PIV PIV

Camera

Thermocouples

array

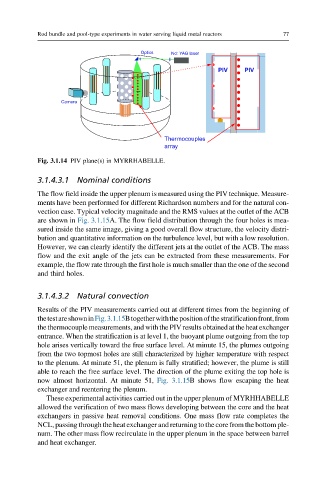

Fig. 3.1.14 PIV plane(s) in MYRRHABELLE.

3.1.4.3.1 Nominal conditions

The flow field inside the upper plenum is measured using the PIV technique. Measure-

ments have been performed for different Richardson numbers and for the natural con-

vection case. Typical velocity magnitude and the RMS values at the outlet of the ACB

are shown in Fig. 3.1.15A. The flow field distribution through the four holes is mea-

sured inside the same image, giving a good overall flow structure, the velocity distri-

bution and quantitative information on the turbulence level, but with a low resolution.

However, we can clearly identify the different jets at the outlet of the ACB. The mass

flow and the exit angle of the jets can be extracted from these measurements. For

example, the flow rate through the first hole is much smaller than the one of the second

and third holes.

3.1.4.3.2 Natural convection

Results of the PIV measurements carried out at different times from the beginning of

thetestareshowninFig.3.1.15Btogetherwiththepositionofthestratificationfront,from

the thermocouple measurements, and with the PIV results obtained at the heat exchanger

entrance. When the stratification is at level 1, the buoyant plume outgoing from the top

hole arises vertically toward the free surface level. At minute 15, the plumes outgoing

from the two topmost holes are still characterized by higher temperature with respect

to the plenum. At minute 51, the plenum is fully stratified; however, the plume is still

able to reach the free surface level. The direction of the plume exiting the top hole is

now almost horizontal. At minute 51, Fig. 3.1.15B shows flow escaping the heat

exchanger and reentering the plenum.

These experimental activities carried out in the upper plenum of MYRHHABELLE

allowed the verification of two mass flows developing between the core and the heat

exchangers in passive heat removal conditions. One mass flow rate completes the

NCL, passing through the heat exchanger and returning to the core from the bottom ple-

num. The other mass flow recirculate in the upper plenum in the space between barrel

and heat exchanger.