Page 203 - Thermal Hydraulics Aspects of Liquid Metal Cooled Nuclear Reactors

P. 203

174 Thermal Hydraulics Aspects of Liquid Metal Cooled Nuclear Reactors

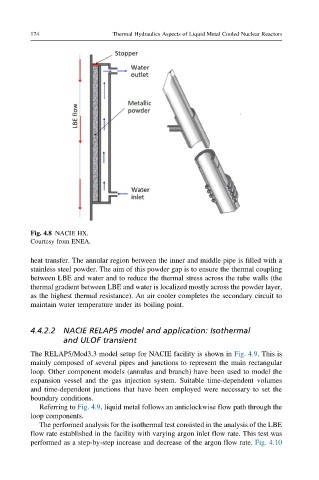

Fig. 4.8 NACIE HX.

Courtesy from ENEA.

heat transfer. The annular region between the inner and middle pipe is filled with a

stainless steel powder. The aim of this powder gap is to ensure the thermal coupling

between LBE and water and to reduce the thermal stress across the tube walls (the

thermal gradient between LBE and water is localized mostly across the powder layer,

as the highest thermal resistance). An air cooler completes the secondary circuit to

maintain water temperature under its boiling point.

4.4.2.2 NACIE RELAP5 model and application: Isothermal

and ULOF transient

The RELAP5/Mod3.3 model setup for NACIE facility is shown in Fig. 4.9. This is

mainly composed of several pipes and junctions to represent the main rectangular

loop. Other component models (annulus and branch) have been used to model the

expansion vessel and the gas injection system. Suitable time-dependent volumes

and time-dependent junctions that have been employed were necessary to set the

boundary conditions.

Referring to Fig. 4.9, liquid metal follows an anticlockwise flow path through the

loop components.

The performed analysis for the isothermal test consisted in the analysis of the LBE

flow rate established in the facility with varying argon inlet flow rate. This test was

performed as a step-by-step increase and decrease of the argon flow rate. Fig. 4.10