Page 206 - Thermal Hydraulics Aspects of Liquid Metal Cooled Nuclear Reactors

P. 206

System thermal hydraulics for liquid metals 177

Exp 206

Exp 306

RELAP5 206

RELAP5 306

LBE flow rate (kg/s) 10 1 m @ const×(m ) 0.33

l

g

10 –4 10 –3

Gas flow rate (kg/s)

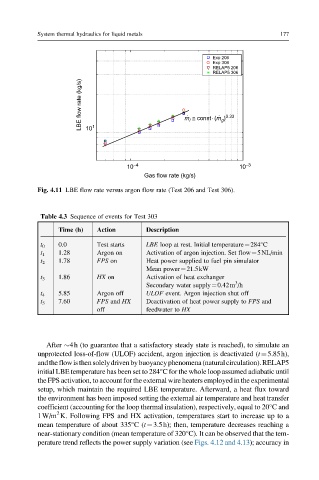

Fig. 4.11 LBE flow rate versus argon flow rate (Test 206 and Test 306).

Table 4.3 Sequence of events for Test 303

Time (h) Action Description

t 0 0.0 Test starts LBE loop at rest. Initial temperature¼284°C

t 1 1.28 Argon on Activation of argon injection. Set flow¼5NL/min

t 2 1.78 FPS on Heat power supplied to fuel pin simulator

Mean power¼21.5kW

t 3 1.86 HX on Activation of heat exchanger

3

Secondary water supply¼0.42m /h

t 4 5.85 Argon off ULOF event. Argon injection shut off

t 5 7.60 FPS and HX Deactivation of heat power supply to FPS and

off feedwater to HX

After 4h (to guarantee that a satisfactory steady state is reached), to simulate an

unprotected loss-of-flow (ULOF) accident, argon injection is deactivated (t¼5.85h),

andtheflowisthensolelydrivenbybuoyancyphenomena(naturalcirculation).RELAP5

initial LBE temperature has been set to 284°C for the whole loop assumed adiabatic until

the FPS activation, to account for the external wire heaters employed in the experimental

setup, which maintain the required LBE temperature. Afterward, a heat flux toward

the environment has been imposed setting the external air temperature and heat transfer

coefficient (accounting for the loop thermal insulation), respectively, equal to 20°Cand

2

1W/m K. Following FPS and HX activation, temperatures start to increase up to a

mean temperature of about 335°C(t¼3.5h); then, temperature decreases reaching a

near-stationary condition (mean temperature of 320°C). It can be observed that the tem-

perature trend reflects the power supply variation (see Figs. 4.12 and 4.13); accuracy in