Page 64 - Time Management

P. 64

Mancini04.qxd 1/16/2003 4:28 PM Page 49

Procrastination: The Thief of Time

3. The task flow is unclear or unplanned. Disorganized plans

are common grounds for procrastination. One useful approach

to attacking the problem of task flow comes from a process 49

control system called TQM.

The TQM Solution

In the late 1940s, W. Edwards Deming, a statistical control ana-

lyst, devised a process control system that came to be known

as Total Quality Management (TQM). He tried to convince sev-

eral U.S. companies to apply it to their assembly lines, but no

one seemed interested. Undaunted, Deming went to Japan,

where business leaders rapidly adopted his theories.

Many people feel that Japan’s subsequent economic suc-

cess was attributable in large measure to Deming’s system. The

truth is far more complex. Japan’s cultural values had a great

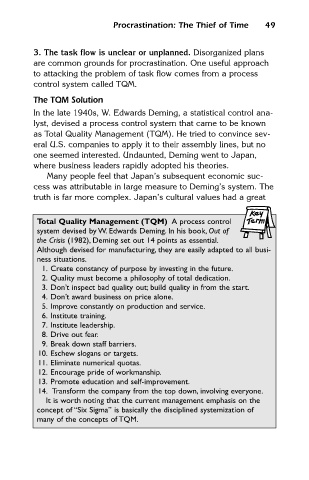

Total Quality Management (TQM) A process control

system devised by W. Edwards Deming. In his book, Out of

the Crisis (1982), Deming set out 14 points as essential.

Although devised for manufacturing, they are easily adapted to all busi-

ness situations.

1. Create constancy of purpose by investing in the future.

2. Quality must become a philosophy of total dedication.

3. Don’t inspect bad quality out; build quality in from the start.

4. Don’t award business on price alone.

5. Improve constantly on production and service.

6. Institute training.

7. Institute leadership.

8. Drive out fear.

9. Break down staff barriers.

10. Eschew slogans or targets.

11. Eliminate numerical quotas.

12. Encourage pride of workmanship.

13. Promote education and self-improvement.

14. Transform the company from the top down, involving everyone.

It is worth noting that the current management emphasis on the

concept of “Six Sigma” is basically the disciplined systemization of

many of the concepts of TQM.