Page 131 - Trenchless Technology Piping Installation and Inspection

P. 131

Coatings and Linings for Potable W ater Pipe Distributions 97

• Types and locations of appurtenances such as valves, fittings,

and fire hydrants

• Number and type of service connections

• Length of time the pipe can be out of service or bypass

requirements

• Site- and project-specific factors (surface and subsurface

conditions)

• Overall cost of the renewal method (material and installation)

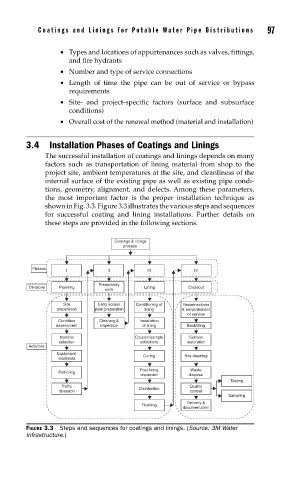

3.4 Installation Phases of Coatings and Linings

The successful installation of coatings and linings depends on many

factors such as transportation of lining material from shop to the

project site, ambient temperatures at the site, and cleanliness of the

internal surface of the existing pipe as well as existing pipe condi-

tions, geometry, alignment, and defects. Among these parameters,

the most important factor is the proper installation technique as

shown in Fig. 3.3. Figure 3.3 illustrates the various steps and sequences

for successful coating and lining installations. Further details on

these steps are provided in the following sections.

Coatings & linings

process

Phases

I II III IV

Preparatory

Divisions Planning Lining Closeout

work

Site Entry access Conditioning of Reconnections

preparation point preparation lining & reinstatement

of service

Condition Cleaning & Installation

assessment inspection of lining Backfilling

Material Coupon/sample Surface

selection collections restoration

Activities

Equipment Curing Site cleaning

readiness

Post-lining Waste

Potholing

inspection disposal

Testing

Traffic Quality

diversion Disinfection control

Sampling

Delivery &

Flushing

documentation

FIGURE 3.3 Steps and sequences for coatings and linings. (Source: 3M Water

Infrastructure.)